International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

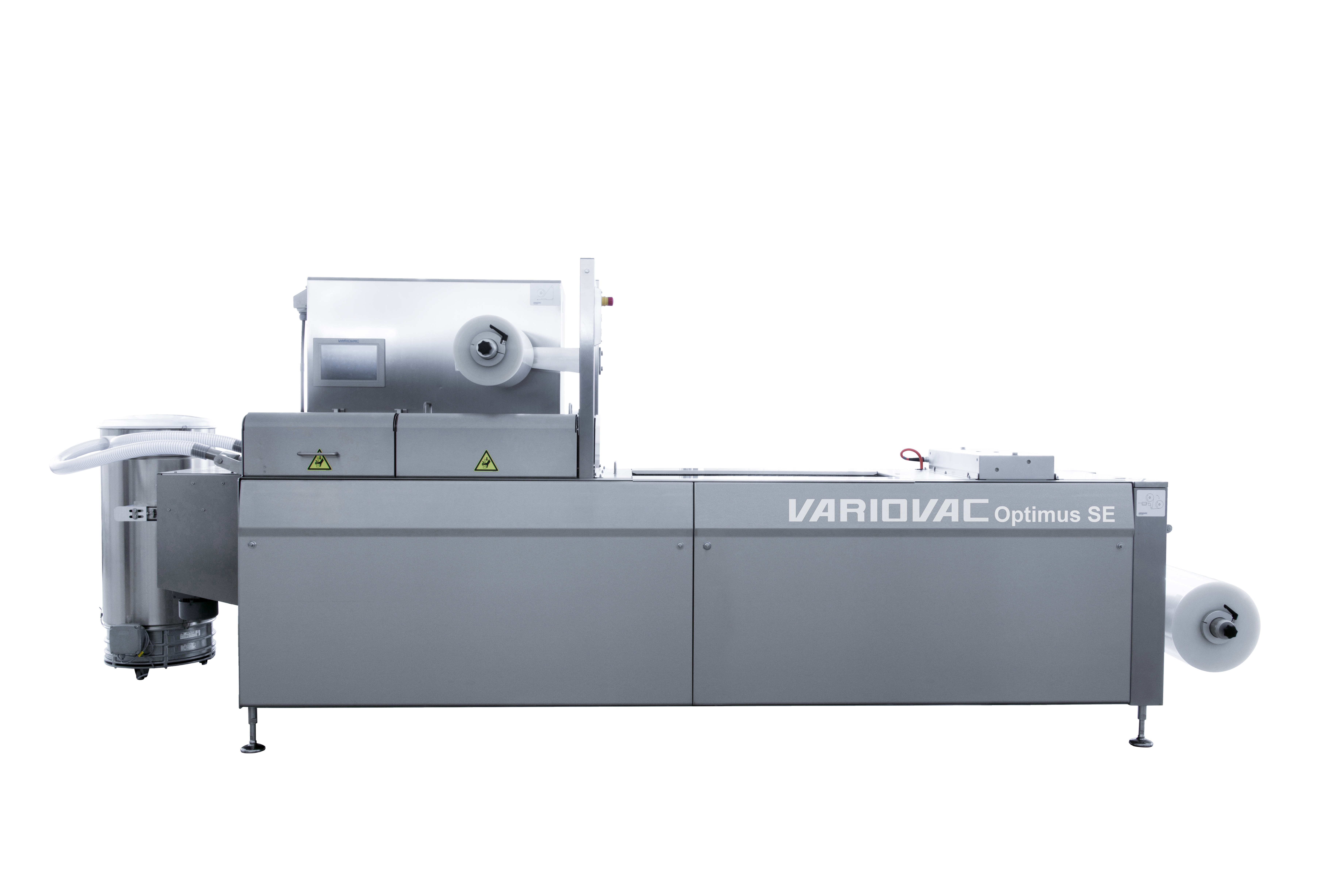

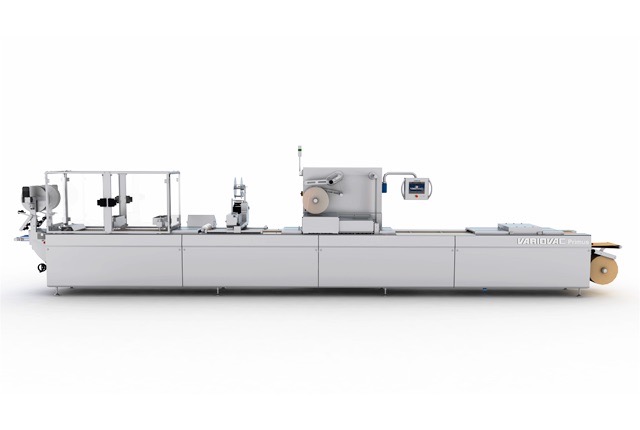

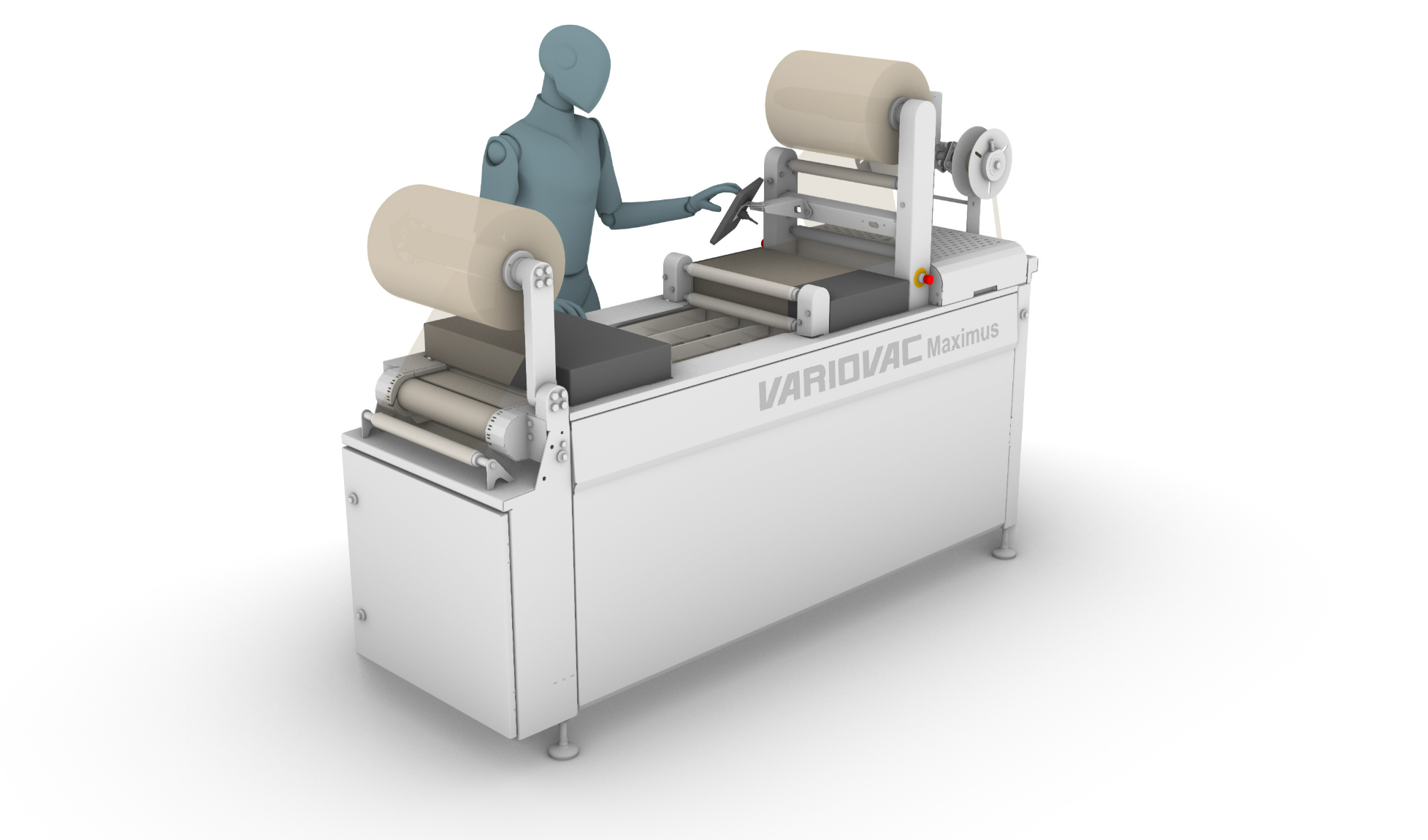

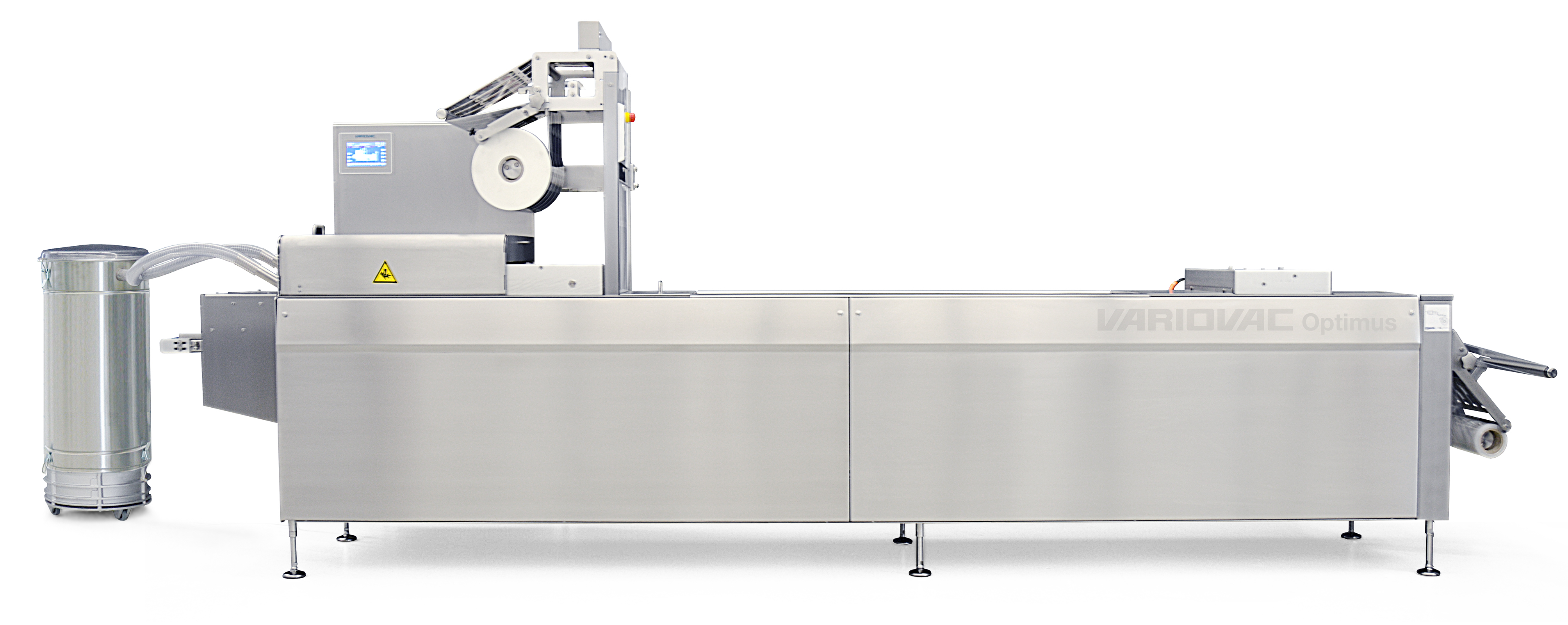

VARIOVAC Rotarius Tray Sealer

VARIOVAC Rotarius Tray Sealer

Description

Our semi-automatic tray sealer Rotarius with its double-tool system owes its name to the practical rotary table: Whilst the machine vacuumises and fumigates the trays in the sealing tool, the machine operator at the front part of the machine can remove the finished trays and immediately insert new ones. This prevents empty runs and increases the packaging output.

The Rotarius can pack fresh, refrigerated and frozen food as well as menu components in ready-made trays. It only requires little storage space and is thus ideally suited for use at small companies. The diversity of possibilities for using the Rotarius are convincing: Be it simply sealing or MAP, skin or gas spooling – it always provides the best packaging for your products (Food, Non-Food, Medicine). Changing the sealing tools – for instance, with different tray sizes – is easy, quick and can be done without any aids.