International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

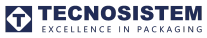

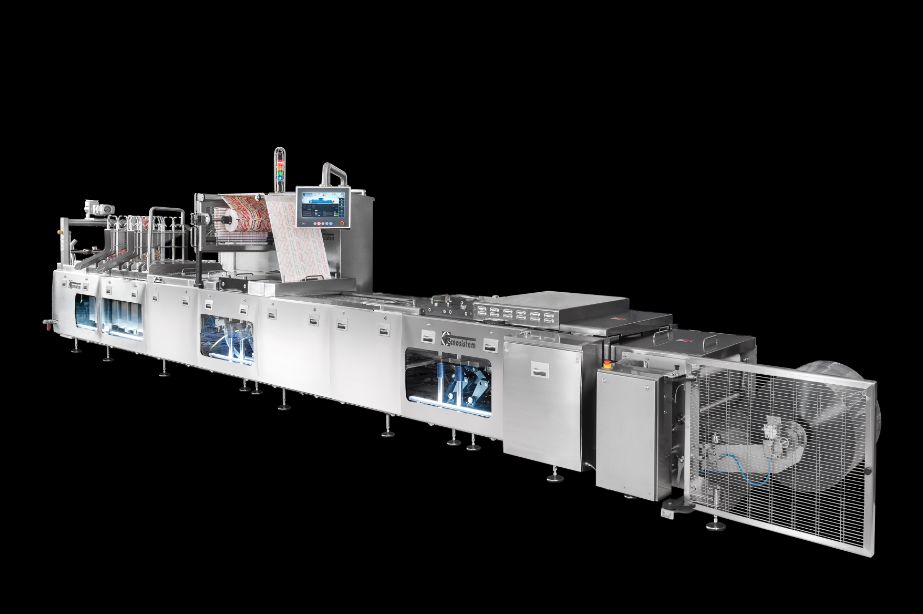

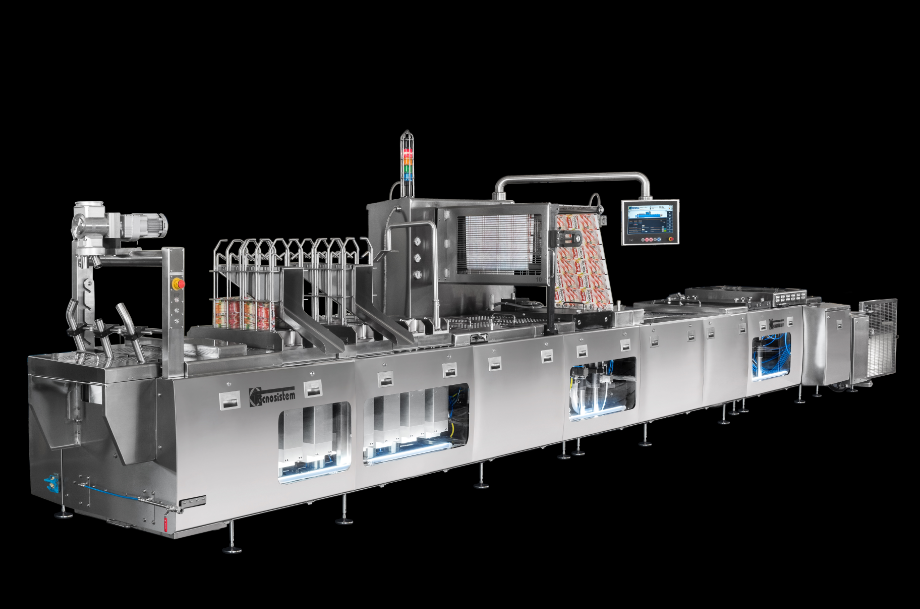

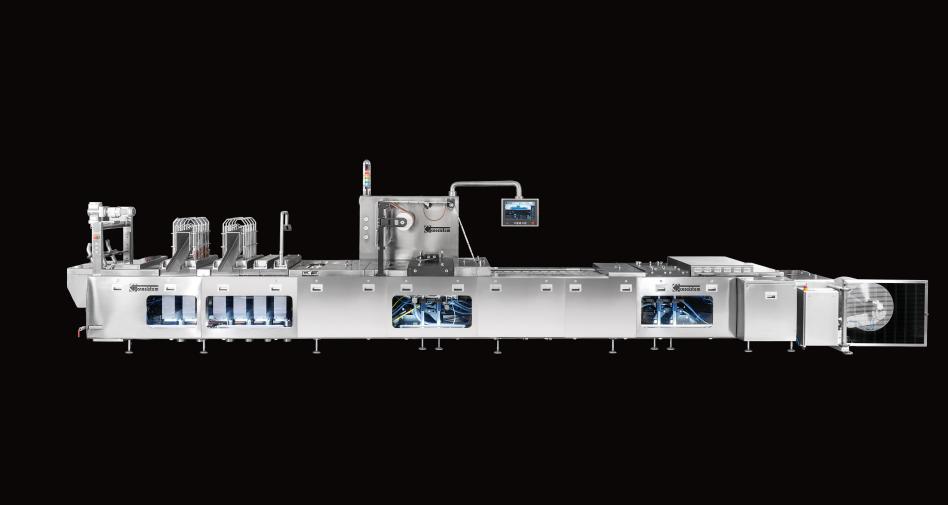

4.0 THERMOFORMING PACKAGING MACHINE

4.0 THERMOFORMING PACKAGING MACHINE

Description

EXCELLENCE MATERIALS, SAFENESS AND HYGIENE

Materials and design of TECNOSISTEM thermoforming machines respects all regulations about safeness and hygiene. In addition to using corrosion resistant materials, as steel INOX AISI 304L and 316, it is provided a sanitation program for an accurate cleaning, in order to assure an absolute hygiene and a long last of each component.

No sharp or critical points, in order to avoid the accumulations of residue and detergents during the process.

RELIABILITY AND CONTINUOUS DEVELOPMENT

Every component is studied, designed and built in our factory; encoded and assembles with care and maniacal attention. This is the additional value, that in the years allowed us to achieve the faith of the most prestigious groups around the world and to put our lines of packaging among the best realities of the packaging area.

The modular construction of thermoforming machines allows the correct adjustment between the relations of space, capability, kind of product to be packaged and additional devices as: automatic slicers, dosage systems, weighing, labelling, automatic lift systems with pick and place and end line automations, at the end of the thermoforming machine.

SKILLED TECHNICAL ASSISTANCE

Each order is manufactured internally thanks to the use of eight CNC centres, wired and tested by high qualified staff that composes the operational staff of a company which is fully oriented to the customer satisfaction.

This grants the customer for the follow up of TECNOSISTEM lines, thanks to an immediate control of every single mechanical part that we produce and integrated with an after-sale service of absolute timeliness and reliability, formed by specialized technicians who offer assistance and advice in each case, and the replacement division which provides to give the availability of necessary spare parts.

Speed and reliability, constantly at your service, are prerogatives that ensure and guarantee a perfect product, ensuring maximum efficiency of production and maintenance of its value in space and time.

Any improvement, made in constant development of the packaging, is immediately moved by our technicians to original spare parts, whose quality and functionality is carefully monitored during their processing.

Our technical assistance is always available and his punctuality in the technical work represents one of the cornerstones of our proven reliability.