FCHL

Working continuously as in Europe's most modern production site

Up to 25% productivity increase and up to 37% manpower saving

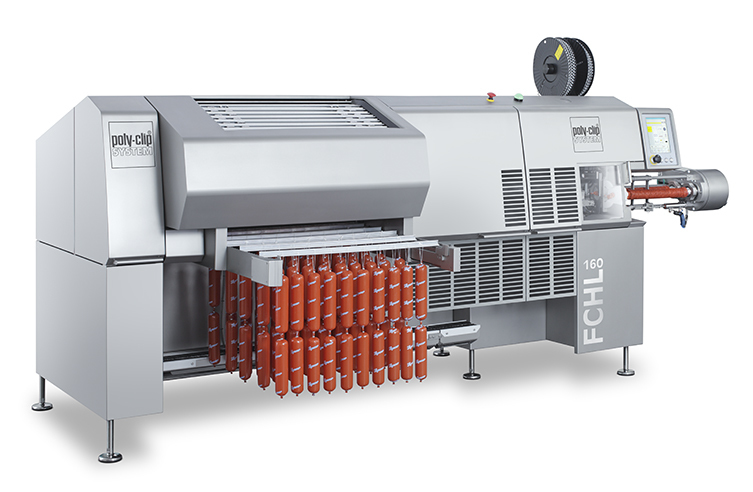

This is what makes it unique: the new Automatic Clipping/Hanging Machine from Poly-clip System combines four production processes in a single machine. In this way it offers a cost saving of up to 37% on manpower while at the same time increasing output by up to 25%.

All-in-one Automatic Machine

This automatic clipping/hanging machine FCHL efficiently combines clipping with simultaneous looping and automatic hanging and positioning of products on the smoke stick. Its high level of automation ensures continuous, reliable production at a positioning rate of up to 85 loop per minute (depending on calibre and process). The automatic clipping/hanging machine thus benefits from all of the advantages of the tried-and-tested FCA 160/120 double-clipper. Continuous, precise positioning on the smoke sticks in the hanging unit permits a higher loading density and thus optimum utilisation of smoking and cooking plant capacity. Compared with the use of a conventional filling line, e.g. comprising an FCA 3430 and filler operating in 2 shifts (8 operators), a productivity increase of up to 25% is achieved with 37% less manpower.

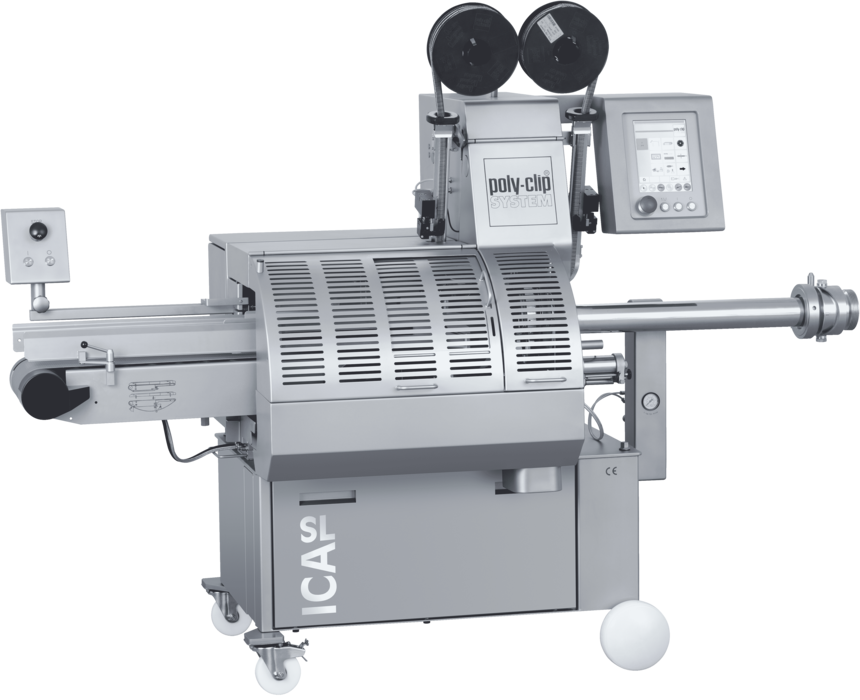

What marks the FCHL out?

This automatic machine has state-of-the-art PC control, which permits simple operation from a single SAFETY TOUCH and provides rapid, smooth start-up after coupling to the filler. Casing re-load occurs while the clip head is stationary. Product parameters are of course retrievable from recipe management, and PC control offers rapid and precise signal processing. Thanks to the intelligent drive control unit, extremely precise loop positioning with product settling results in more products on the smoke stick, and thus in a higher output.

Productivity increases further with the ASL-R

The output rate increase totals 40% when the Automatic Sausage Loader ASL-R takes over loading of the smoke trolleys. At the same time, the manpower requirement can be reduced to 3 operators in 2-shift operation, which corresponds to a total saving of 60 % on operating staff. This increase in efficiency is made possible by the ASL-R, a fully-automatic robot-controlled machine for discharging smoke sticks and loading them into smoke trolleys – the robot does not require work breaks and never suffers from any illness. The ASL-R brings the output to 6 smoke sticks per minute, which it automatically positions in the smoke trolley with great precision. The innovative automatic clipping/hanging machine FCHL turns out products in the calibre range from 38 to 100 mm and processes metal or plastic smoke sticks which are suitable for automation (800 to 1,250 mm).

As usual, Poly-clip System offers the highest processing quality and a robust hygienic design. The machine’s compact construction and powerful servo drive are designed for continuous operation. Central lubrication keeps wear and tear to a minimum, and easy access to the machine for the purposes of maintenance and thorough cleaning is afforded by large maintenance flaps and by means of a special cleaning position of the clip head.