International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

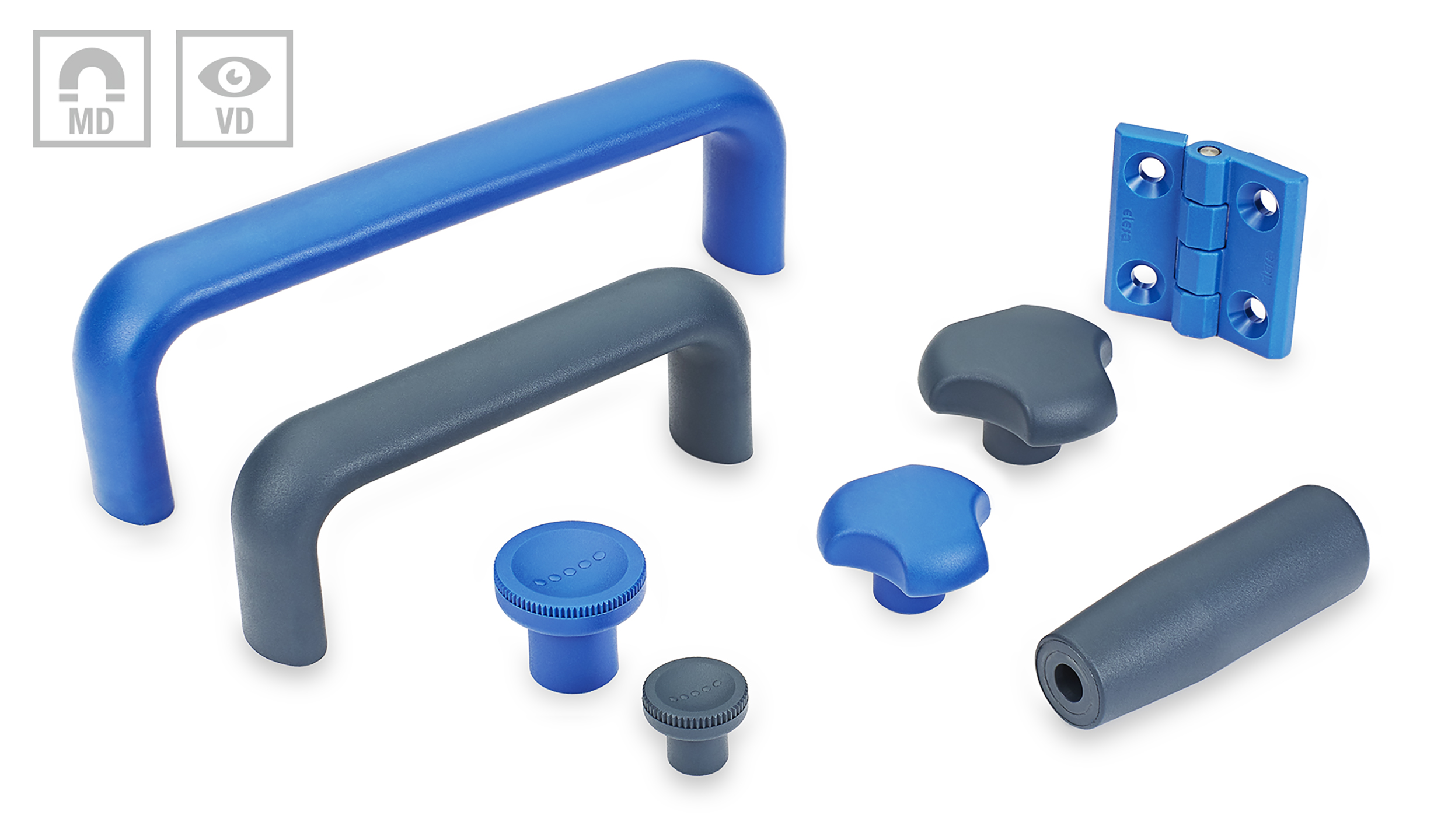

Hygienic Design for Standard Parts

Hygienic Design for Standard Parts

Description

Ganter develops sealed standard stainless steel elements that meet stringent hygiene requirements. Maximum hygiene is one of the absolutely basic prerequisites wherever food is produced. However, hygiene also plays a major role in other sectors — from medical technology and the pharmaceutical industry to manufacturers of dispersion paints. Today, it is all about producing products without preservative additives — and this is only possible in production environments which have high purity levels. Since even the tiniest weak points can cause entire production lines to be contaminated, Ganter decided to develop a special series of standard parts that meet the very high EHEDG requirements and the 3-A Sanitary Standard.

Ganter offers a variety of knobs, handles, clamping levers, leveling feet and screws under the label "Hygienic Design", all of which are optimized for minimal contamination and easy cleaning. Stainless steel — with either ground or polished surfaces — is the material used in all of these cases. The maximum surface roughness is kept below Ra 0.8 μm, so that dirt particles cannot adhere and can be reliably removed during cleaning. Find out more in the internet at www.ganternorm.com