International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

On-line MAP Gas Analyzers - Dansensor® MAP Check 3

On-line MAP Gas Analyzers - Dansensor® MAP Check 3

Description

MAP Package gas analyzers for quality assurance and gas flushing control

Our online MAP gas analyzers continuously extract and monitor packaging gas from the Modified Atmosphere Packaging line to ensure that the equipment and gas mixing system deliver a desirable protective atmosphere which meets the requirements for prolonged shelf-life products within the food & beverage and pharmaceutical industry.

The Dansensor series of on-line gas analyzers are equipped with user-friendly touch-screen interfaces and offer excellent data-logging and traceability options, which make them suitable for:

- MAP Quality Assurance

- Control of gas flushing processes

- Streamlining Modified Atmosphere Packaging processes

Compared to quality control, an on-line gas analyzer is a cost-effective solution which minimizes the use of excess packaging gas and reduces the need for time-consuming repackaging of products.

Dansensor® MAP Check 3

Dansensor® MAP Check 3 continuous gas analyzer is designed to precisely monitor gas content on vertical and horizontal flow packaging machines.

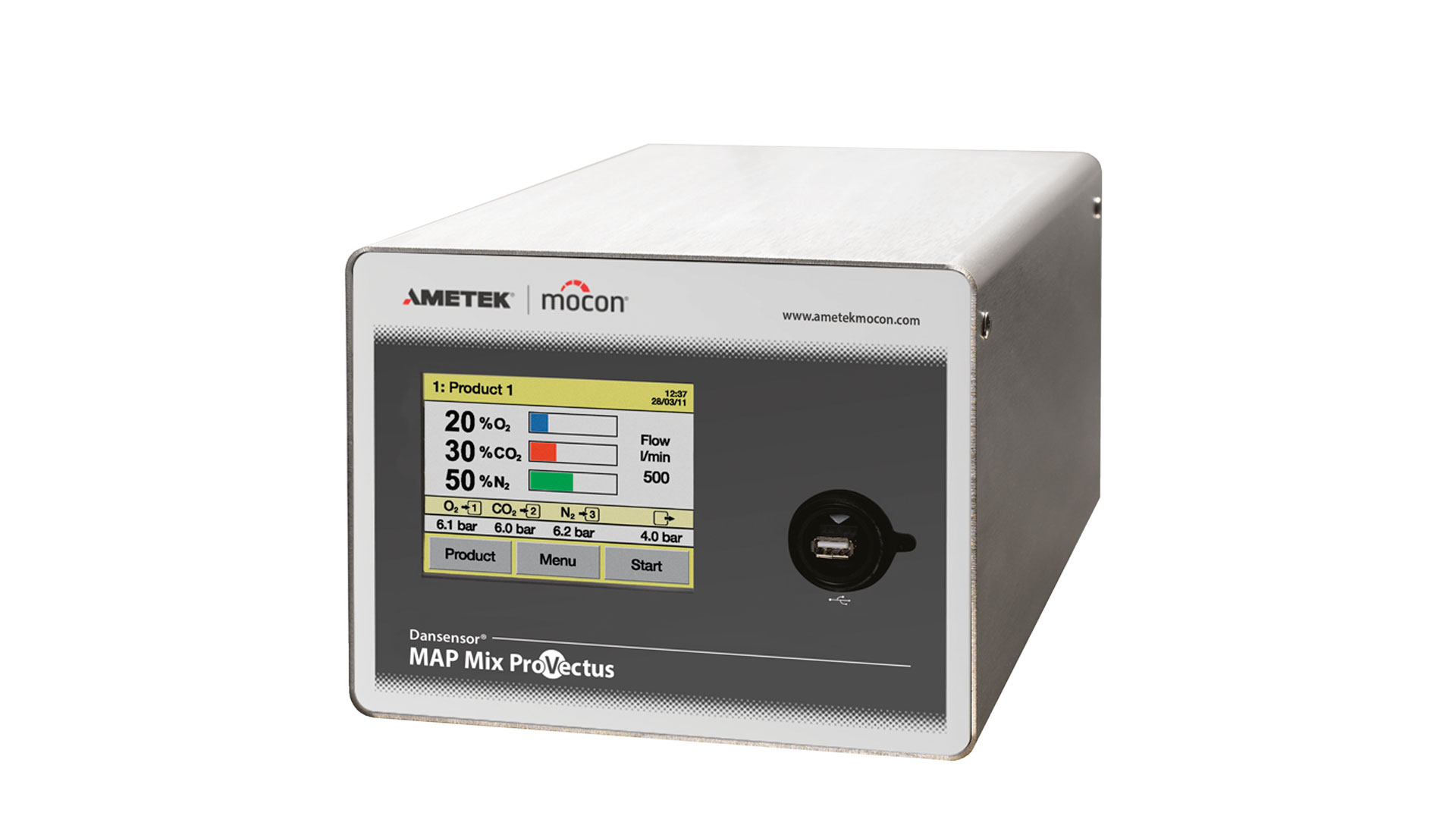

- Major gas savings with optional GasSave function or when paired with Dansensor® MAP Mix Provectus® gas mixer

- On-line Quality Assurance of every package – more efficiently and with reduced labor and waste costs compared to manual testing

- logging and displaying of actual gas consumption with the GasSave function for easy traceability

- automatic stopping of the packaging machine if preset limits are exceeded, helping to avoid recalls and repacking

- Reduced CO2 levels in the work area to protect employees

Dansensor® MAP Check 3 Vacuum

The Dansensor® MAP Check 3 Vacuum gas analyzer provides on-line quality assurance of thermoforming and tray sealing lines by measuring gas composition on a continuous basis.

- Oxygen or combined oxygen and carbon dioxide measurement

- Continuous monitoring and effective control of every packaging cycle

- Automatic production halt in case of exceeded gas limits to avoid recalls or repackaging

- User configurable alarms for low and high gas concentrations