International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

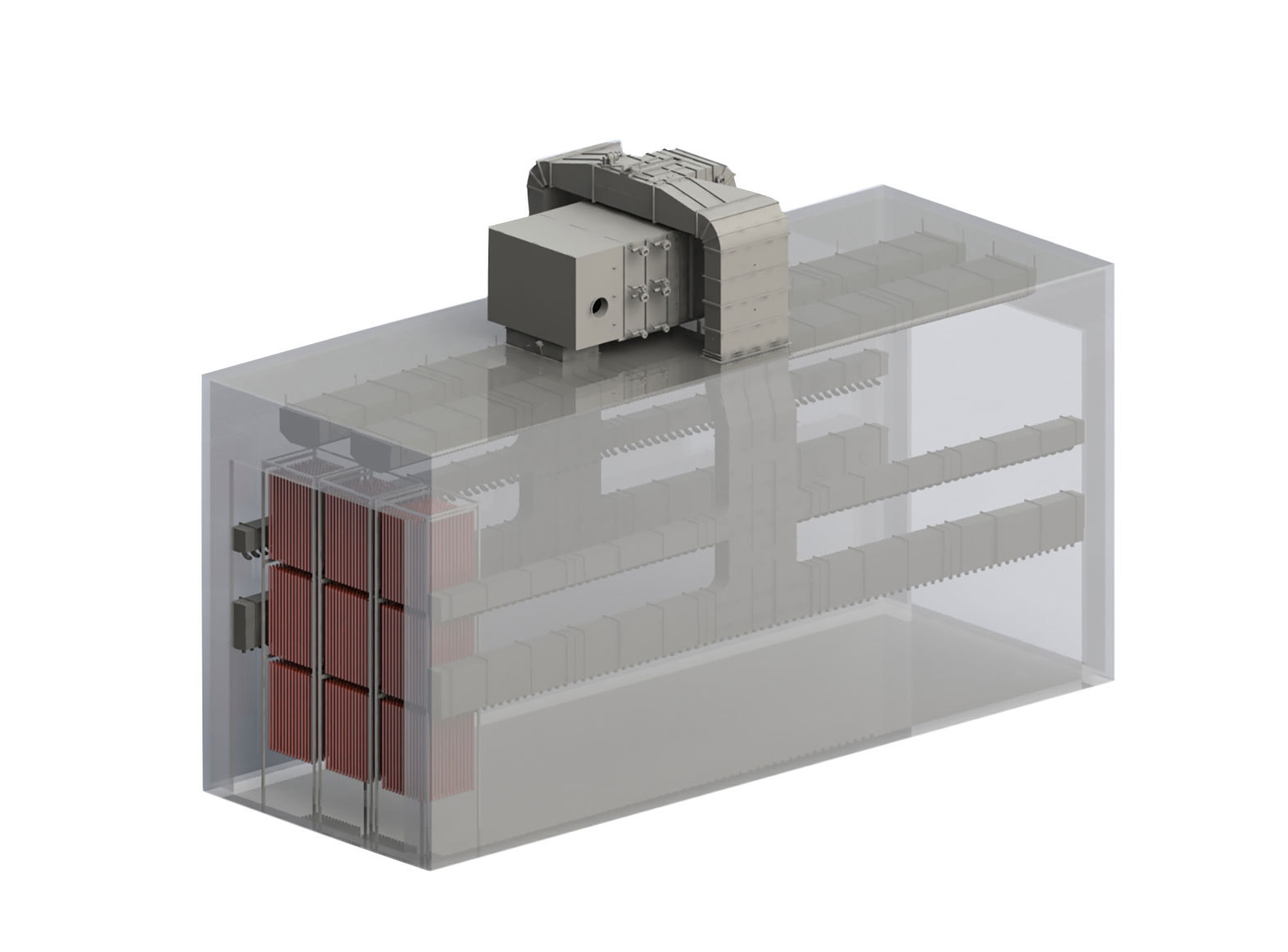

Semi-continuous Batch Systems

Description

Advantages

“Inline” production:

The production process is performed inline with the semi-continuous loading system, i. e. there is no processing delay between filling and packaging. The location of every product during the thermal processing is always known and controlled.

100% separation between low and high risk areas:

The airtight transfer zone between the entry and exit sides allows the separation of production and packaging areas (“low-risk“, “high-risk“). You can therefore produce bacteriologically safe products without contamination.

Integration:

The system can be integrated into the production area due to upstream and downstream automation and can therefore result in an efficient package solution adapted to your production requirements.

Characteristics

Use:

Each of the process chambers are separated by an intermediate transfer zone (hinged or vertical lifting doors). A system may consist of two or more zones.

Possible processing:

- Drying / smoking / cooking transferred to intensive cooling downstream

- Cooking transferred to intensive cooling downstream

- Other combinations on request

Floor transport/ Roller conveyor:

An electric drive system ensures smooth transportation.

Overhead rail conveyor:

An electric drive system ensures smooth transportation.