International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

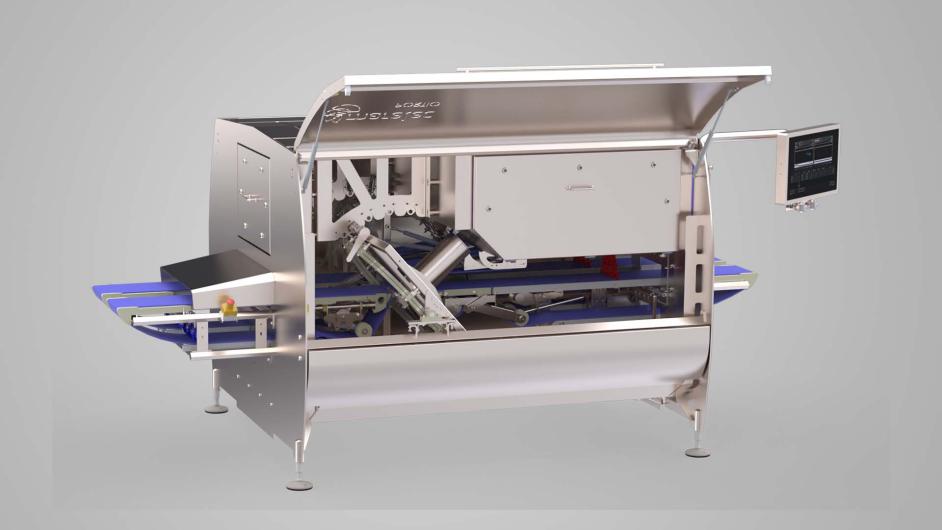

Intelligent Portion Cutter

Intelligent Portion Cutter

Description

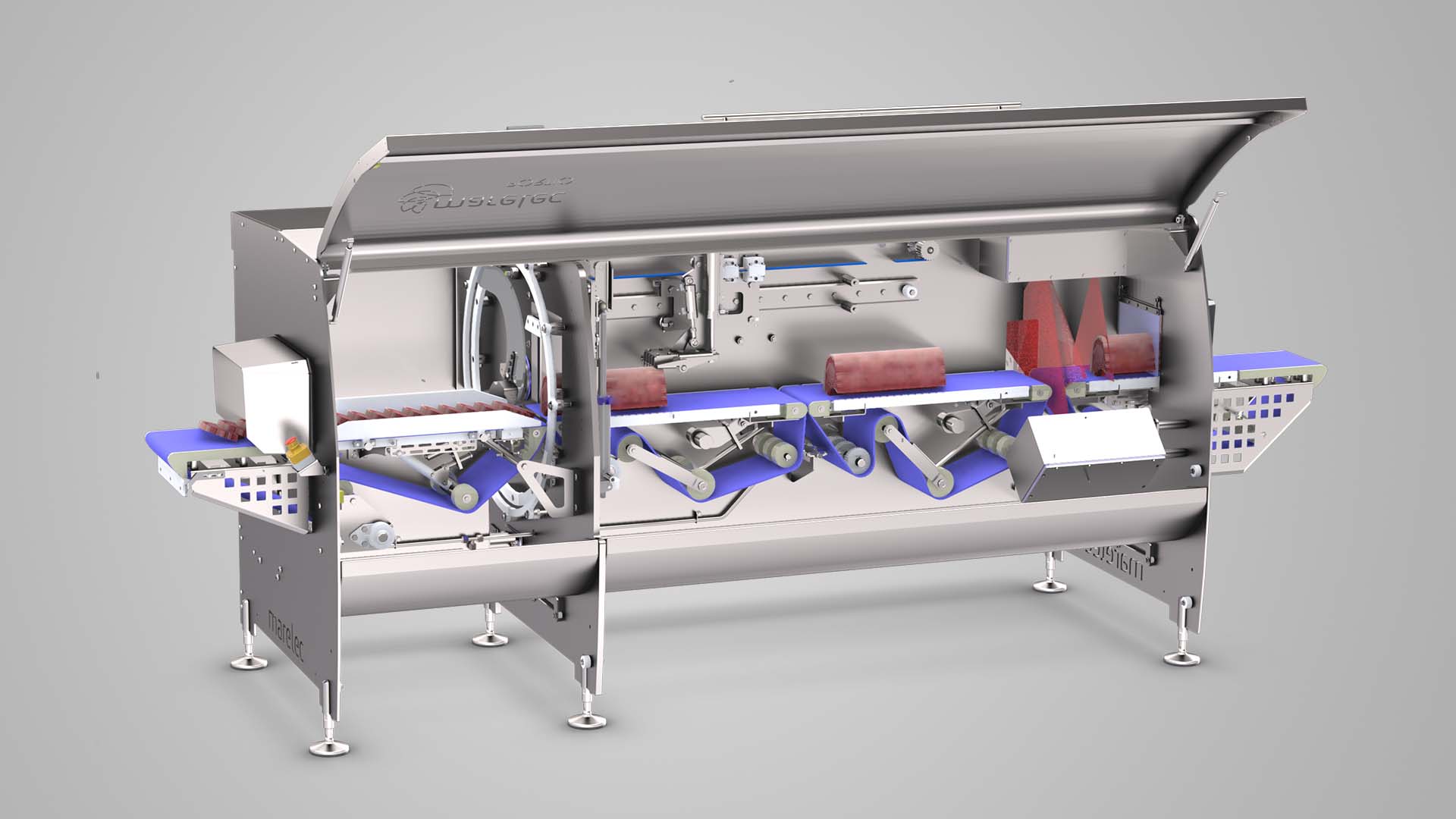

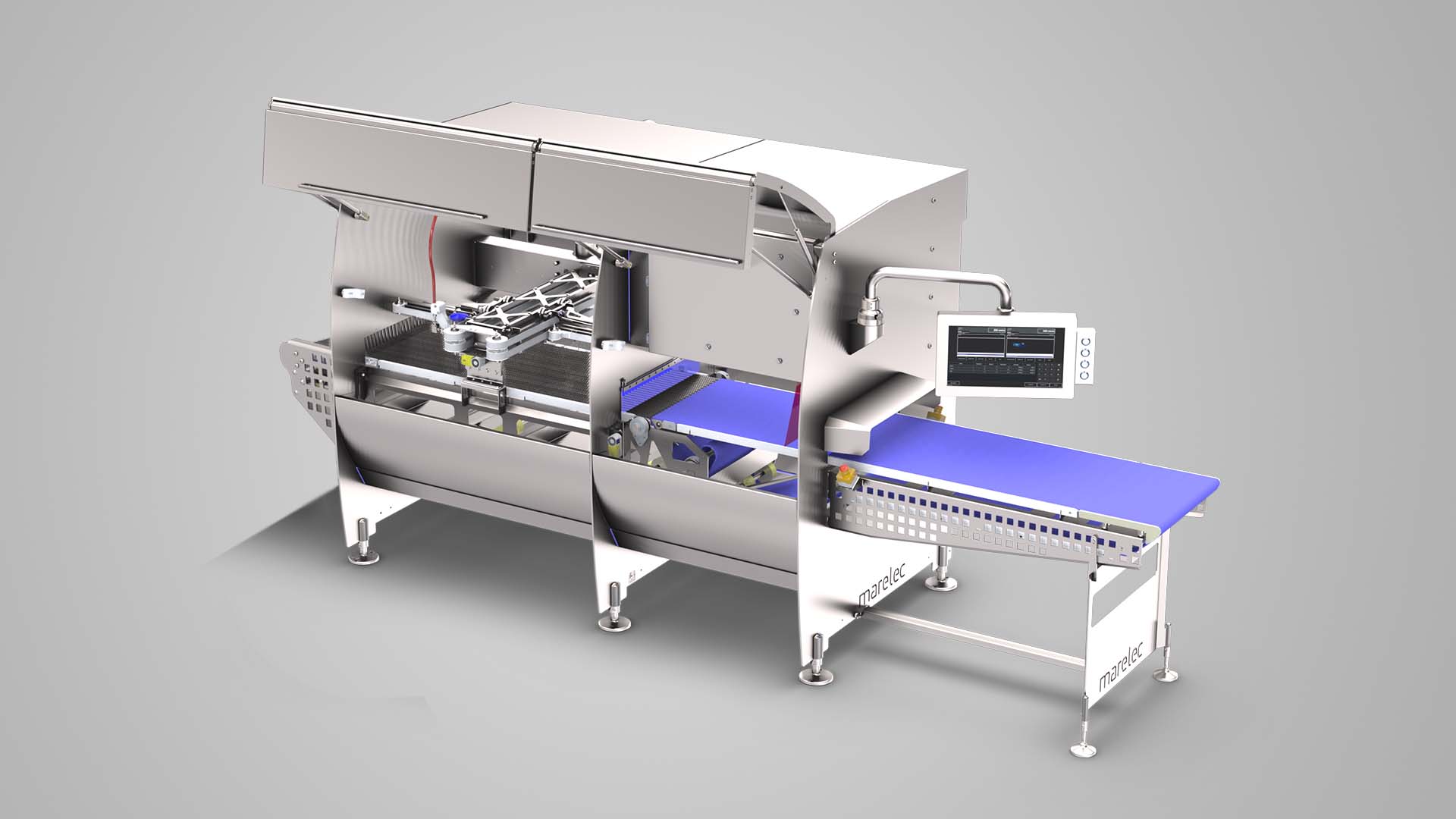

MARELEC Food Technologies has become a market leader with its PORTIO range. These portion cutters cut fresh meat or poultry into portions of fixed weight of fixed thickness. The machines use the proven technology of laser guided cameras to scan the volume. Knowing the density, the intelligence calculates instantly where to cut to make the portion with the programmed weight.

Production efficiency is guaranteed as the software always calculates to go to zero waste or maximum yield.

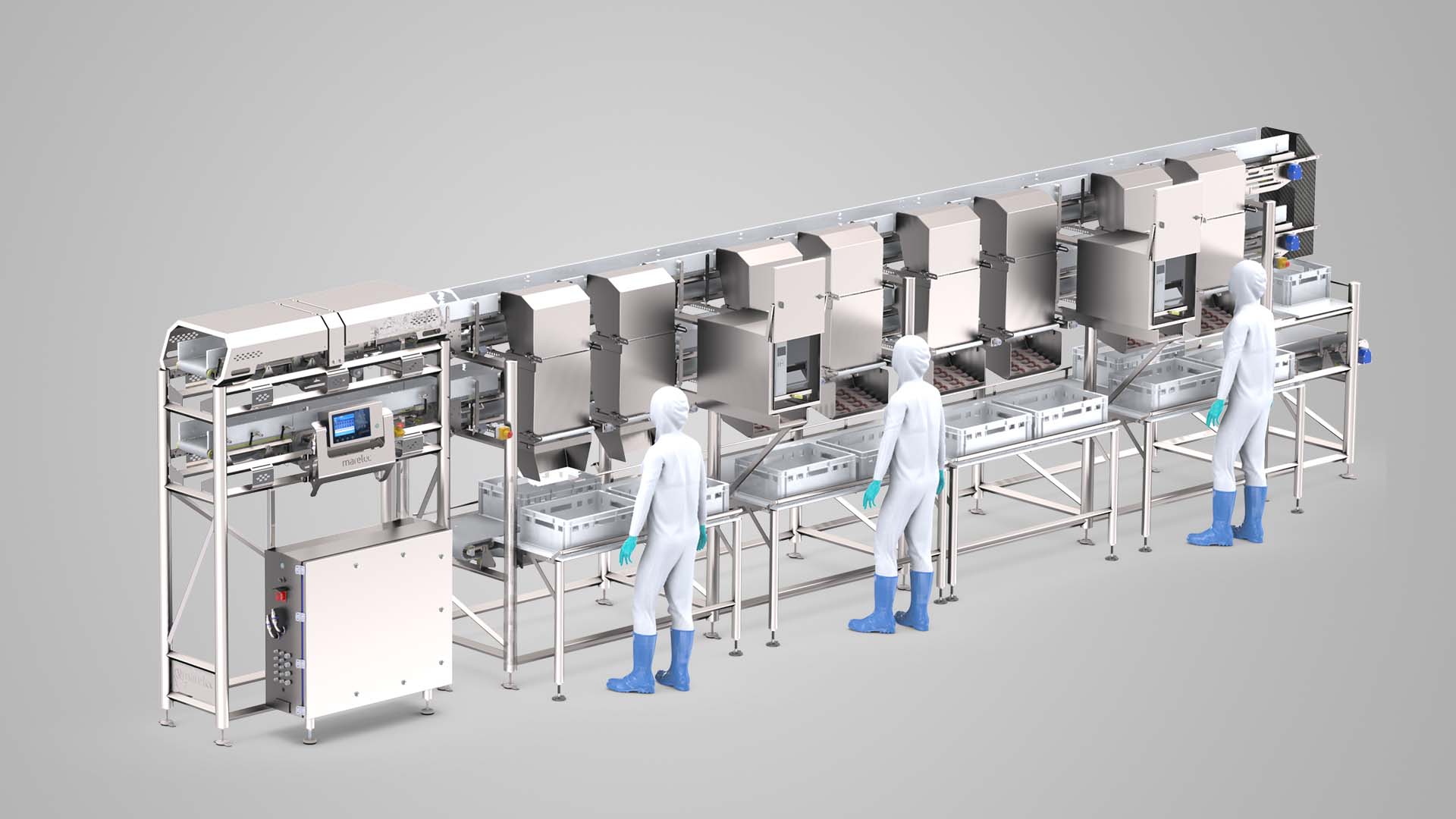

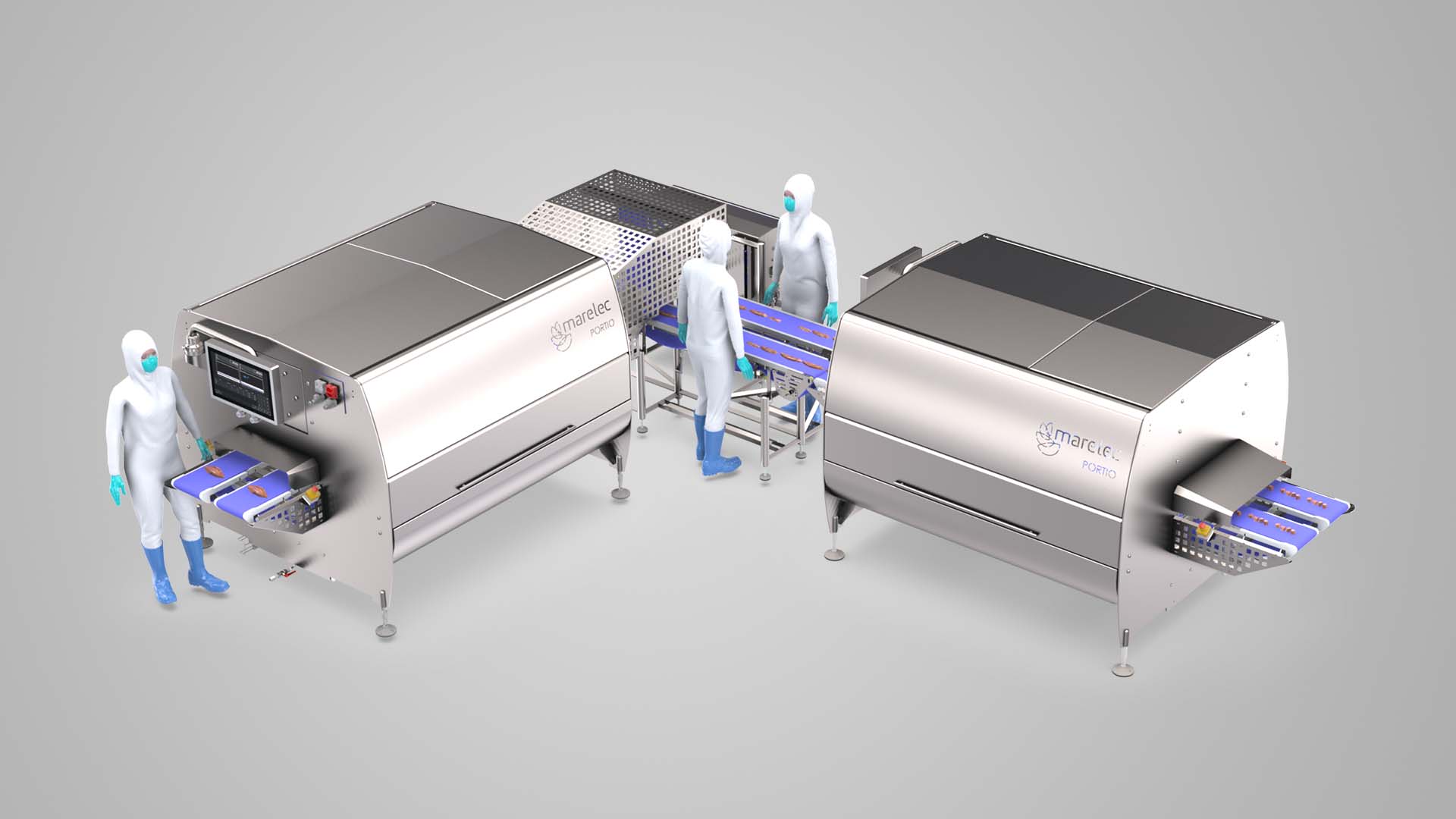

The MARELEC range has grown tremendously over the last years to accommodate all possible applications. We have Portion Cutters available that cut under an angle as well as dual lanes for high capacity portioning and a variety of wide belts to portion large meat products.

All MARELEC PORTIOs are designed for optimum cleaning and hygiene. The machines can be opened completely for easy access. Operating is easy to allow fast fine tuning of the programs. Options exist to calculate the density and to hold the products in place when cutting.

The PORTIO can be placed in line with a grader, to maximize the yields. In this case, the machine selects the optimal cutting pattern to reduce trim.