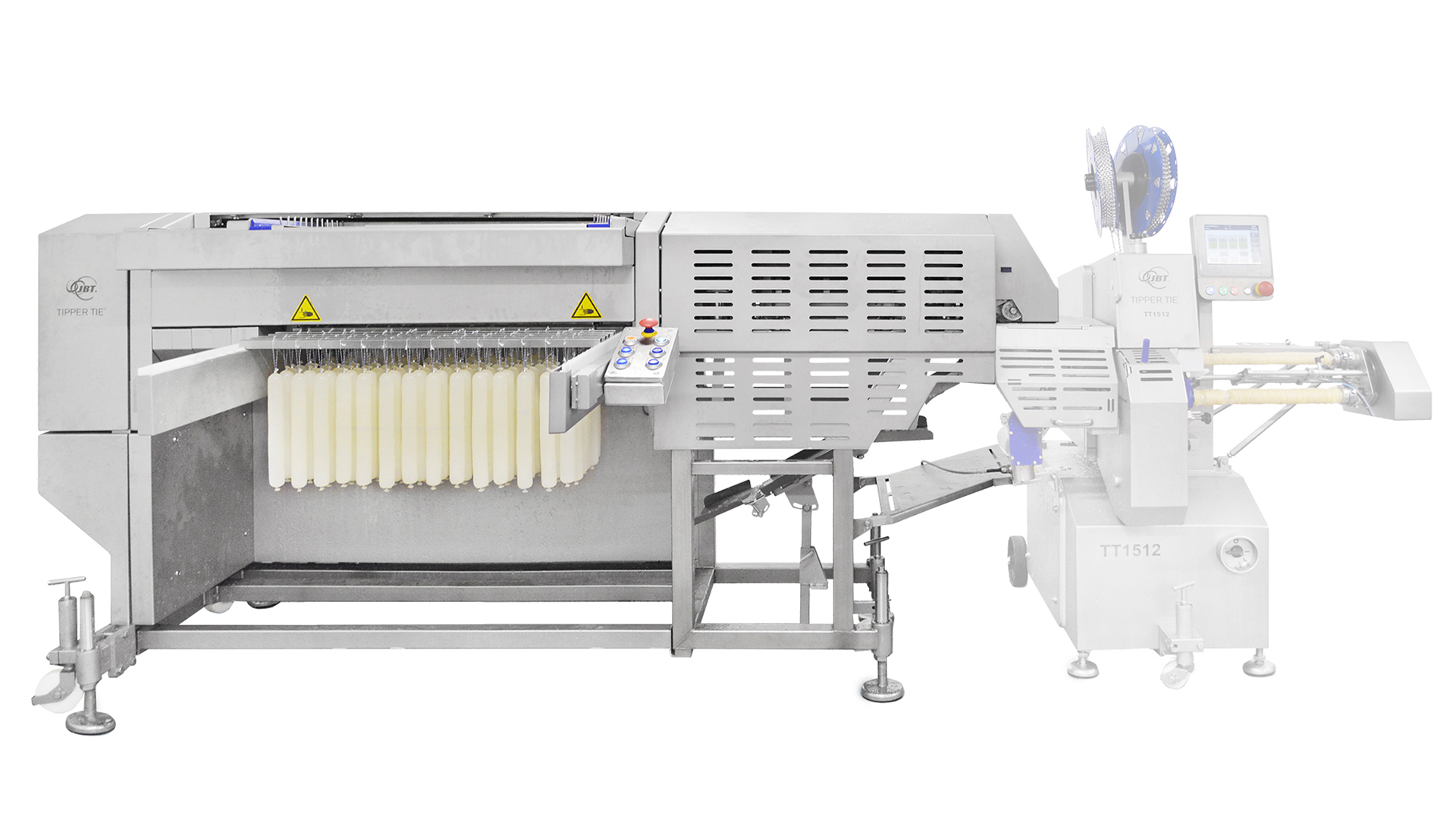

GREATER PRODUCTIVITY THROUGH AUTOMATION - the TIPPER TIE TTStick Automated Hanging Technology

Flexibility

Flexibility in production combined with a high degree of automation is what characterizes the new TTStick. With this machine, TIPPER TIE offers state-of-the-art suspension technology for an even more efficient process. It is ideal for producing portioned or strings of sausages that need to be hung.

The TTStick safely and precisely suspends all sausages with plastic, fibrous, and collagen casings of calibers Ø 20–120 mm with a maximum sausage/string length of up to 800 mm. Depending on the product, it can hang up to 100 loops/minute on the smoking sticks.

The machine can accommodate up to 26 empty smoking sticks in the magazine, while the customer can still decide between 3 different finished buffer sizes (8, 12, or 16 completed sticks) providing more customer flexibility.

Technical Highlights

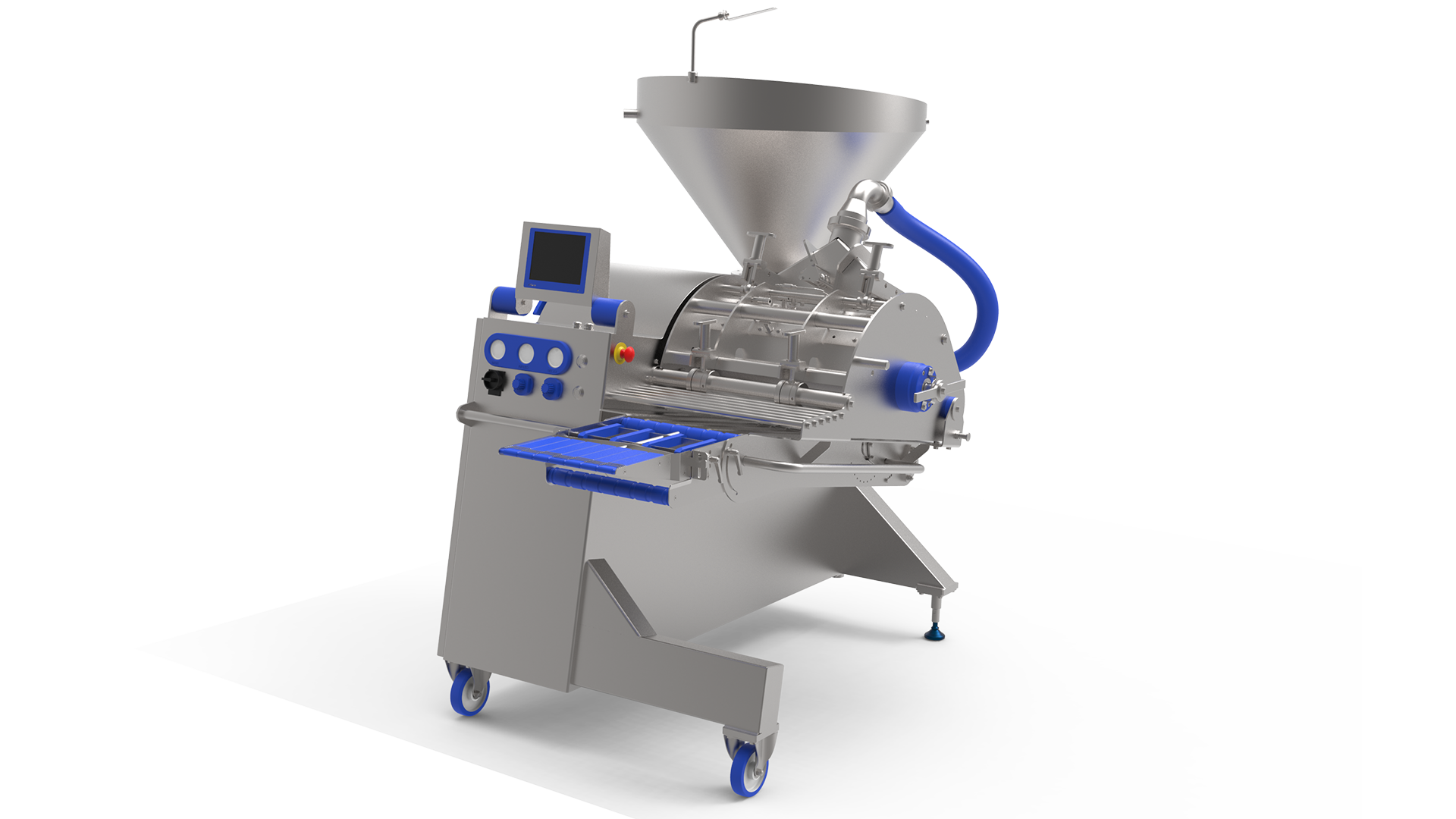

The TTStick is connected to one of TIPPER TIE’s high-speed automatic clippers, either a TT1512 or TT1815. The loops are transferred directly from the automatic string loop feeder of the double clipper without any handling required. The string of sausages is then automatically placed on the smoking stick by the TTStick.

The controls for both the clipper and TTStick are managed by the clipper Human Machine Interface or HMI. Individual positioning of the string loops can be specified and saved in the recipe section of the HMI, saving time and helping to achieve up to 25% higher utilization of the smoking stick (and subsequently the smoking trolley, cooking, or smoking chambers), leading to more production capacity as well as a more efficient production.

A key aspect of this is the efficiency of the smoking stick replacement system. The TTStick has a servo-driven smoke stick exchange instead of pneumatics, which allows more control over the smoke stick exchange with less noise and vibration. When the specified number of loops are precisely located onto the smoking stick, the now filled stick is ejected into a buffer in only 600 ms, and a new one is supplied from the magazine. This means uninterrupted production even at high speeds which is what makes the incredible 100 loops per minute speed possible. The filled smoking stick is now ready to be moved to a rack or trolley either by the operator or with an automatic system for even greater savings. Additionally, the full stick buffer has a safety stop which is activated as soon as the delivery table is full. A visual signal warns the operator in advance to help prevent unnecessary stoppage.

The TTStick ensures high production with little downtime while increasing the utilization of drying rooms and smokehouses, all with minimal operator interaction.

The TTStick is designed for docking with a TT1512 or TT1815. Both can be connected to the TTStick without much effort.

Handling

Easy handling, fast production, improved efficiency, and productivity: This is the result of the integration between the TIPPER TIE TTStick and the high-speed TT1815 or TT1512 automatic double clipper from TIPPER TIE.

To change the loops or clips, only the string loop housing needs to be opened. The TTStick does not have to be disconnected for that. To achieve even shorter downtimes, the double clipper is equipped with a parallel turret. This enables new casing to be added while the machine is running. The casing change can take place without opening the upper section of the clipping machine. This results in a casing change that takes just a few seconds, leaving your production virtually uninterrupted.

Additionally, transportation and handling have been optimized as well. The TTStick has wheels on the machine footing. This allows you to easily move the machine without additional help.

Control

TIPPER TIE’s TTStick is operated and controlled using the HMI from the TT1815 or TT1512 automatic double clipper. This means the machines are perfectly integrated from a control standpoint. This gives the operator a very simple and clear overview of both machines and makes recipe management and product changes very easy.

This innovative operating system with easy-to-understand pictograms is also state-of-the-art. For example, the number of sausages per smoke stick and their distance/spacing can be set easily. An integrated large internal program memory ensures that many different programs can be stored without any problems. Any operators already familiar with the TT family of automatic clipping machines will quickly learn the TTStick controls.

The controls themselves are driven by maintenance-free servo motors in the TTStick to ensure fast, efficient, and repeatable operation. New innovations have made the TTStick even more efficient and the operation smoother, thanks to the elimination of pneumatic cylinders. TIPPER TIE’s TTStick is smart, efficient, and reliable!

Cleaning & Maintenance

The TTStick is very easy to maintain and service. Smooth, stainless surfaces with a three percent gradient are design elements that allow fast, hygienic cleaning. An integrated safety control system monitors production. In the event of a machine error, the system stops the line, and the TTStick, clipper, and stuffer go into standby mode. Imminent maintenance work is communicated to the operator on the touch screen, and interactive graphics help display potential faults and error sources so the machine can be rapidly put back into service.