International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

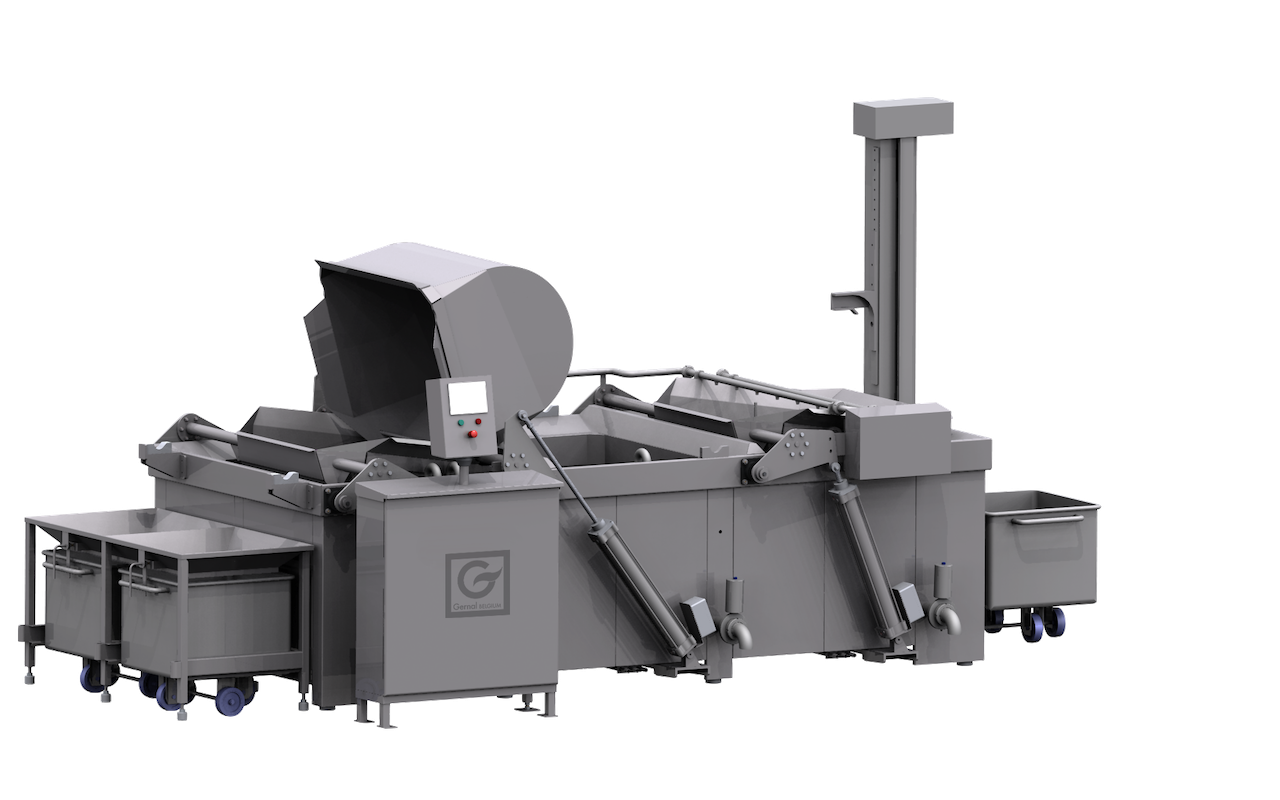

Description

Gernal pasteurisers with counter pressure are designed for quick pasteurisation of ready meals packed in foil. As a result, the storage life of the product is doubled, without any loss of taste or freshness in colour.

Features: extremely safe, short cooking times, a wide range of applications, robust

A computer-controlled program uses steam and compressed air to build up a constant counter pressure, so that trays are no longer deformed during heating and cooling. This reduces to a minimum the risk of welded seams tearing and packaging opening.

Due to the very short cooking times, Gernal pressure cookers are highly suitable for a broad range of meals, ranging from simple soups to exquisite casseroles.

The equipment can be optionally operated with electricity or steam. Cooling facilities are provided by running water or ice water.

To be able to withstand the constant counter pressure, these units are provided with a heavy, solid construction.

SVS-3000 process tracking and visualisation software is also available, assuring 100% quality control and process monitoring.

The Gernal product range includes various pasteurisers,with sizes ranging from 2,500 to 15,000 litres.