Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

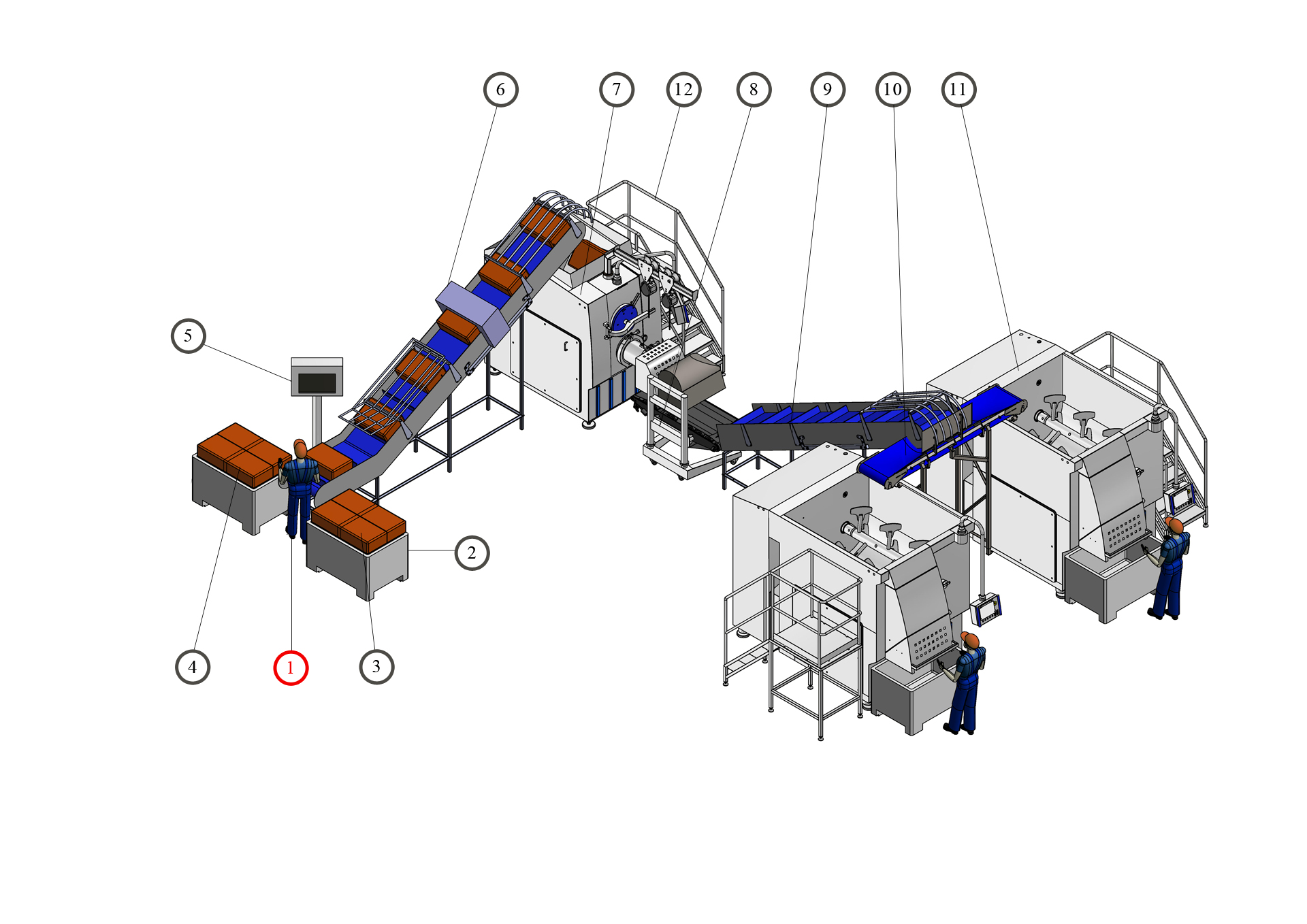

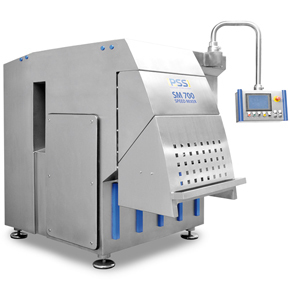

PSS SFV 720: Speed Filler Vacuum

Beschreibung

The PSS SFV Speed Filler Vacuum is a multifunctional device designed for medium and large operations in the food industry. It gives perfect filling of meat products and other food products.

The device guarantees effective usage and ensures a continual process of metering and filling of processed materials. The processed material is fed into the hopper, where it is caught by two feeding worms that gently move it towards the metering device.

The PSS SFV can also be used with the additional grinding attachment, which ensures quality final grinding and subsequent material filling into appropriate casings. The PSS SFV is as standard equipped with a vacuum system, which inhibits the possible creation of air bubbles in the final product.

Options- Grinder – attachement with a standard set of grinding plates, and as an option – the plates from 2,5 to 16 mm (SFV 720)

- Worms and plates for grinding of cooled meat pieces to 3 kg (SFV 720)

- Set of worms with different step

- Lifting device for 200l trolleys

- Dosing device of pulse type for all types of casings – natural or synthetic

Dosing tube: standard Ø 12 mm;

Dosing tube: optional Ø 10 mm, Ø 17 mm, Ø 20 mm;

Filling capacity: up to 8 450 kg/h

(usage of worms with rising step t=39 mm)

up to 17 500 kg/h

(usage of worms with rising step t=64 mm)

Maximum working pressure (calculated): 50 bar Vacuum system: 57 m3/h Regulation range of batch weight for production of frankfurters and sausages: 25 – 100 000 g Output – production of cooked products, batch weight 1000 g with use of automatic clipping machine: up to 2 400 kg/h Regulation range of batch weight for production of salami products: 50 – 100 000 g Deviation of weight for final product: ± 1% Minimal temperature of raw material: -4 °C (for specific type of raw material) Hopper volume: 250 l Total input: 24,1 kW Speed regulation of worms and filling: yes Speed regulation of mixing spiral: yes Machine weight: 1 061 kg Main dimensions (LxWxH): 1315 mm x 1310 mm x 2035 mm Voltage network: 3/PE/N 50Hz 230/400V TN-C-S Standardized AC voltage: 230/400 V ± 10% Control voltage: 230/24 V AC 99 optional programs, color graphic display, intuitive control, hygienic design Filler mode: Output with batch weight 50 g – pulse type (cellulose / collagen casings): up to 180 pcs/min. * Output with batch weight 50 g – pulse type

(natural calibrated casings): up to 180 pcs/min. * Output with batch weight 100 g – pulse type

(cellulose / collagen casings): up to 180 pcs/min. * Output with batch weight 100 g – pulse type

(natural calibrated casings): up to 150 pcs/min. * Grinder mode Cutting of minced meat on 3 mm hole plate: 6000 kg/hour Cutting of minced meat on 18 mm hole plate: 7000 kg/hour

* Results achieved on the dosing tube with diameter of 12 mm in stable 24 hours load

Adresse

PSS SVIDNIK, a.s.

Sovietskych hrdinov 460 /114

089 01 Svidník

Slovakia

Telefon+421 54/786 21 11

Fax+421 54/752 09 04