Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

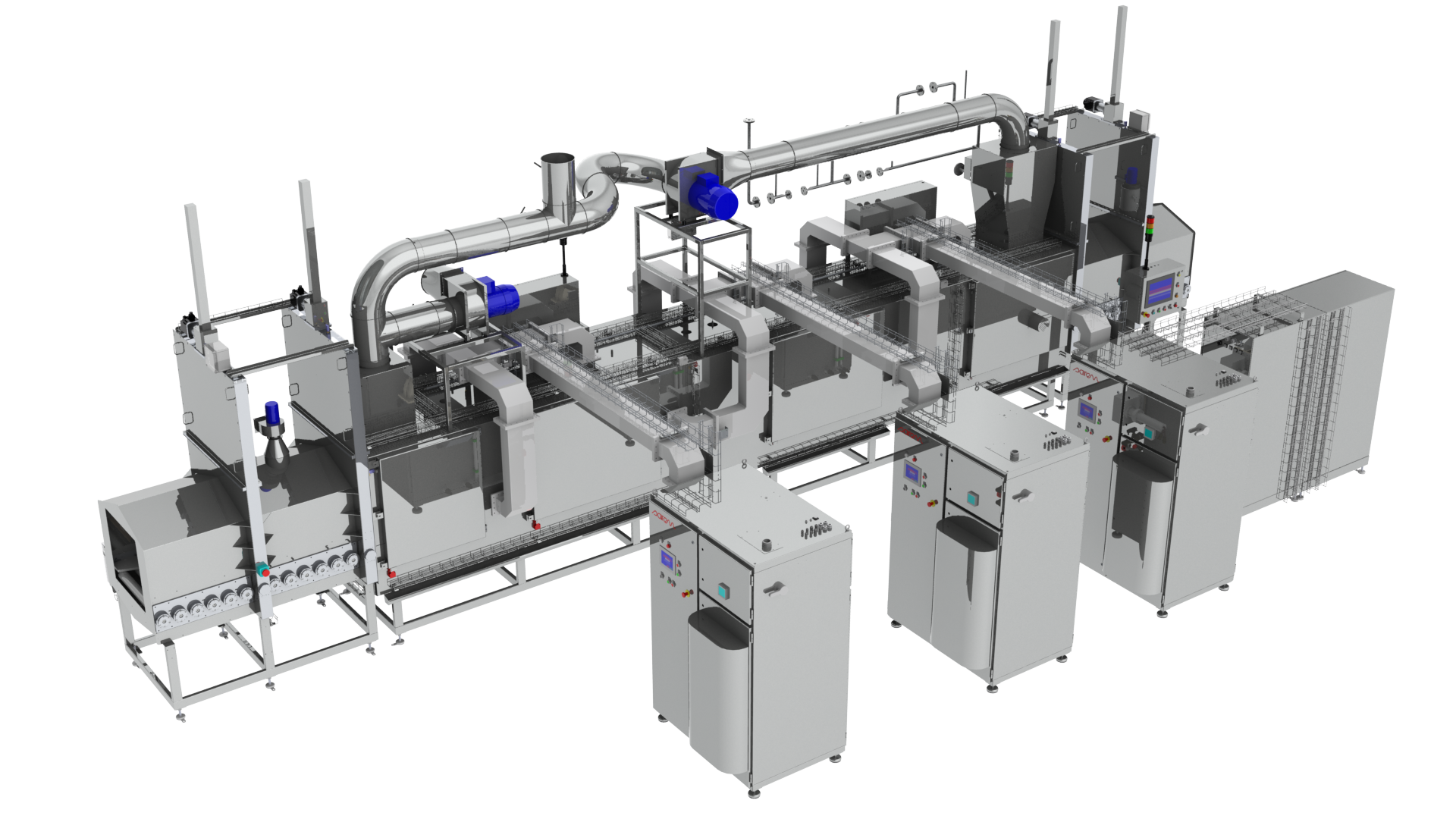

Microwave Tempering Ovens

Beschreibung

Microwave and RF ovens are perfectly adapted to thaw meat and fish products. These technologies work with all kinds of meat: beef, pork, poultry… They are effective on raw or processed products (like sausages for example) without oxidation or alteration of the

product’s organoleptic properties.

- The temperature homogeneity of +/- 2 °C throughout the food block allows for better post processing of your products.

- MW and RF tempering processes allow you to heat significant quantities of products, in the form of pieces or blocks of meat and fish, with or without packaging.

- This tempering process is extremely fast: you will be able to process several tens of tons of meat products in one day versus several days with traditional processes.

- Thanks to the speed and performance of the MW and RF tempering process, bacterial development is significantly reduced. Your meat products are tempered in a totally safe way.

- Unlike classical tempering processes such as tempering chambers, microwave and RF processes significantly reduce drip loss. It’s a very profitable way to defrost your meat products.

Speed : while classical defrosting and tempering methods take hours or days to temper or defrost your food products, MW and RF technologies take from 3 to 20 minutes. In addition, there is no need to waste time unpacking your products. They can easily be tempered or defrosted in their original packaging (plastic film, cardboard, plastic box, etc).

Savings : the speed and uniformity of MW and RF processes minimize product drip losses and

degradation. By completely eliminating weight losses caused by conventional defrosting methods (which can represent up to 8% of the ingredients to be transformed) you immediately improve your raw material yield. The payback can be as short as 6 to 12 months. In addition to saving money, you also save space thanks to the small footprint of our tempering equipment. Our machines replace large tempering or defrosting rooms and eliminate the need for space to house the pallets waiting to temper slowly in the traditional way.

Safety : thanks to the rapidity of MW and RF tempering and defrosting processes, bacterial growth is limited. Defrosting food products with a traditional method can take hours or even days, increasing the health risk. On demand, and for optimal food safety, our tunnels allow you to separate incoming and outgoing product flows to avoid cross contamination. In addition, microwave and RF technologies are safe and SAIREM’s systems are fitted with sensors to prevent microwave/RF leakage

Quality : unlike some traditional methods, MW and RF tempering and defrosting preserves all the organoleptic properties of your food products: color, weight, taste, vitamins, nutriments… Moreover, the temperature homogeneity of +/- 1 °C throughout the food block allows for better post processing of your products.