Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

Beschreibung

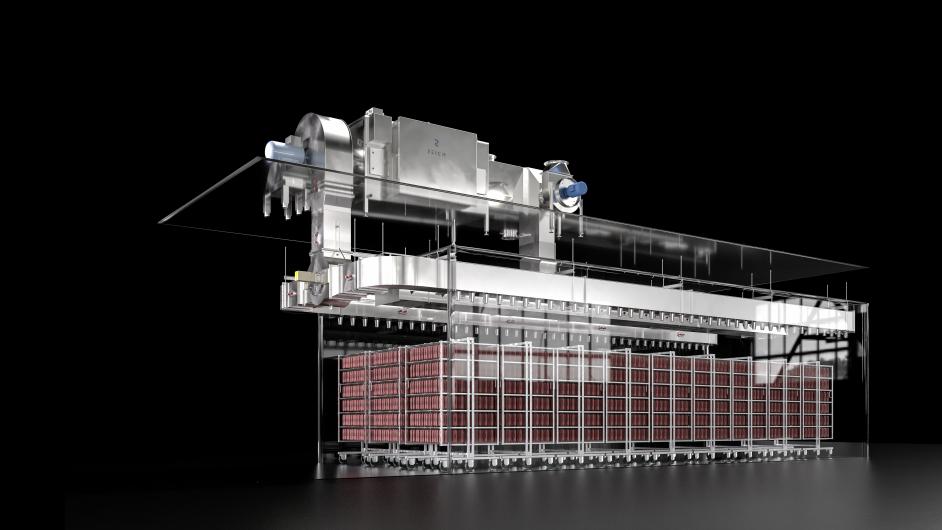

Klima-Reifeanlagen stellen höchste Anforderungen an das Fachwissen der Ingenieure und Technologen. Die Herstellung von Rohwurst, Rohschinken und anderen gereiften und luftgetrockneten Produkten erfordert eine exakte individuelle Abstimmung der Leistungsparameter und Geometrie der Anlage auf die Anforderungen der Produkte und Räumlichkeiten. Dabei stehen exakte Ergebnisse, intelligente und ressourcenschonende Prozesse und eine optimale Produktbehandlung im Vordergrund.

Das Kernstück jeder AIRMASTER® ClimaStar-Reifeanlage ist das zentrale Luftaufbereitungsaggregat. Darin wird die aus dem Behandlungsraum zurückgeführte Luft konditioniert, das heißt, je nach Bedarf gekühlt, entfeuchtet, befeuchtet und beheizt.

Entsprechend dem Behandlungsprozess wird von außen Frischluft zugeführt oder witterungsunabhängig im Umluftbetrieb gearbeitet. Anlagen aus dem Hause REICH sind mit großdimensionierten Luftkühlern für ein schnelles und effizientes Entfeuchten ausgestattet.

Die aufbereitete Luft wird dem Behandlungsraum durch einen zentralen Ventilator über Einblaskanäle zugeführt. Ein programmierbares Wechselklappensystem sorgt dafür, dass der Luftstrom nacheinander über jede Wagenreihe strömen kann und gleichmäßige Ergebnisse gewährleistet sind.

Die intelligente Klimasteuerung der AIRMASTER®-Reifeanlagen ermöglicht eine exakte, homogene und energieeffizienteTrocknung und Reifung. Das stufenlos regelbare Umluftsystem wird dabei durch die Wasserabgabe der Produkte gesteuert, sodass zum Beispiel eine Trockenrandbildung an der kostbaren Ware verhindert wird. In Kombination mit dem REICH

ECOMIZER, einem modernen Frischluft-Enthalpie-System, kann die Trocknung der Ware über die angesaugte Frischluft energieoptimiert werden. Ein Sensor misst dazu ständig die Klimadaten der Außenluft und überträgt diese an die Steuerung. Bei geeigneten Außenluftzuständen wird die Kühlung nur noch zur Temperierung der Umluft genutzt, aber nicht mehr zur Trocknung. Der REICH ECOMIZER bietet somit ein großes Energieeinsparpotenzial.

Die AIRMASTER® ClimaStar-Anlagen sind für jede gewünschte Anzahl von Wagen lieferbar.

AIRMASTER® KKRI ClimaStar: Vorreifen, Trocknen, Kalträuchern

Klima-Vorreifeanlagen der Serie KKRI sind für alle Vorreife-, Trocknungs- und Kaltrauchverfahren von Rohwurst und Rohschinken sowie Halbdauerwaren ausgelegt. Weitere Anwendungen sind die Lufttrocknung und Kalträucherung von speziellen Fleischwaren wie zum Beispiel Biltong und Beef Jerky sowie Fisch und vegetarische Produkte. Die Regelbereiche für Temperatur und Feuchte liegen bei +16 °C bis +28 °C und 65 % bis 95 % relativer Luftfeuchtigkeit. Für Produktgruppen wie zum Beispiel Summer Sausage und dünnkalibrige Rohwürstchen können auch höhere Temperaturbereiche bis +45 °C erreicht werden. Die Luftströmung über die Produkte erfolgt von unten nach oben.

AIRMASTER® KRAI ClimaStar: Vorreifen, Trocknen

Klima-Vorreifeanlagen der Serie KRAI sind für alle Reife-, Trocknungs- und Nachreifeverfahren von Rohwurst und Rohschinken sowie Halbdauerwaren ausgelegt. Weitere Anwendungen sind die Lufttrocknung von speziellen Fleischwaren wie zum Beispiel Biltong und Beef Jerky sowie Fisch oder vegetarischen Produkten. Die Regelbereiche für Temperatur und Feuchte liegen bei +16 °C bis +28 °C und 65 % bis 95 % relativer Luftfeuchtigkeit. Für Produktgruppen wie zum Beispiel dünnkalibrige Rohwürstchen können auch höhere Temperaturbereiche bis +45 °C erreicht werden. Die Luftströmung über die Produkte erfolgt von unten nach oben.

AIRMASTER® KNRI ClimaStar: Nachreifen, Trocknen, Lagern

Klima-Nachreifeanlagen der Serie KNRI sind für die Nachreifung, Trocknung und Lagerung von Rohwurst und Rohschinken sowie Halbdauerwaren ausgelegt.

Die Regelbereiche für Temperatur und Feuchte liegen bei +10 °C bis +18 °C und 65 % bis 90 % relativer Luftfeuchtigkeit. Die Luftströmung über die Produkte erfolgt von oben nach unten. Durch die Kombination mit der entgegengesetzten Strömungsrichtung in der Vorreifeanlage (KKRI oder KRAI) entsteht ein perfekt gleichmäßiges Endprodukt. KNRI-Anlagen sind konfigurierbar für Wagenhöhen bis zu 6 Meter.

Vorteile AIRMASTER® CLIMASTAR

- Exakte, produktschonende Behandlung durch präzise Klimasteuerung

- Energieeffizient durch intelligente Prozesse und Frischluft-Enthalpie-System REICH ECOMIZER

- Witterungsunabhängig durch Umluftkonditionierung

- Gleichmäßige Ergebnisse durch programmierbares Wechselklappensystem

- Stufenlose Drehzahlregelung der Ventilatoren

- Hohe Luftleistungen für schnelle Prozesse

- Aggregat und Kanalsystem komplett Edelstahl 1.4301

- Vollautomatische CIP-Reinigung

- KKRI mit allen REICH Raucherzeugersystemen kombinierbar