Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

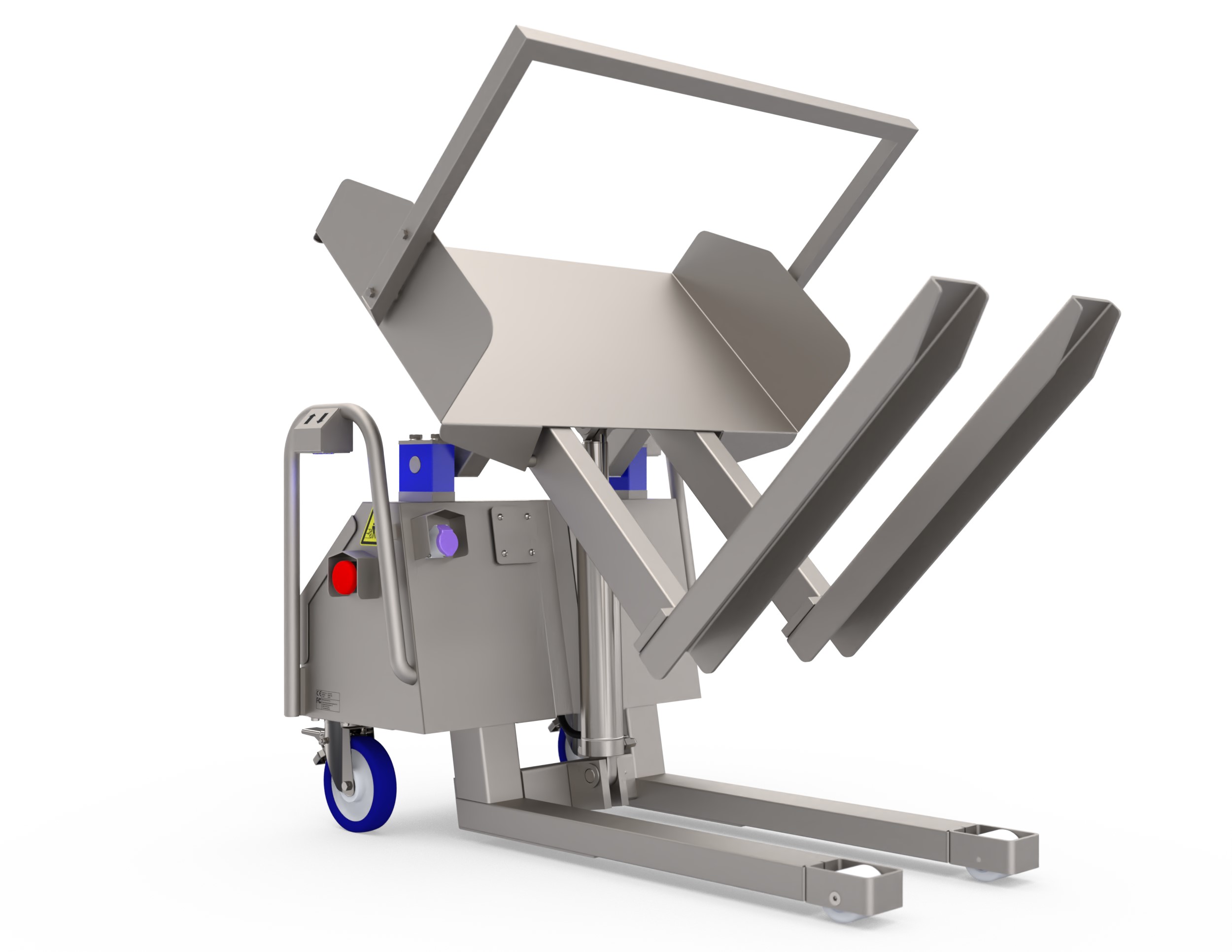

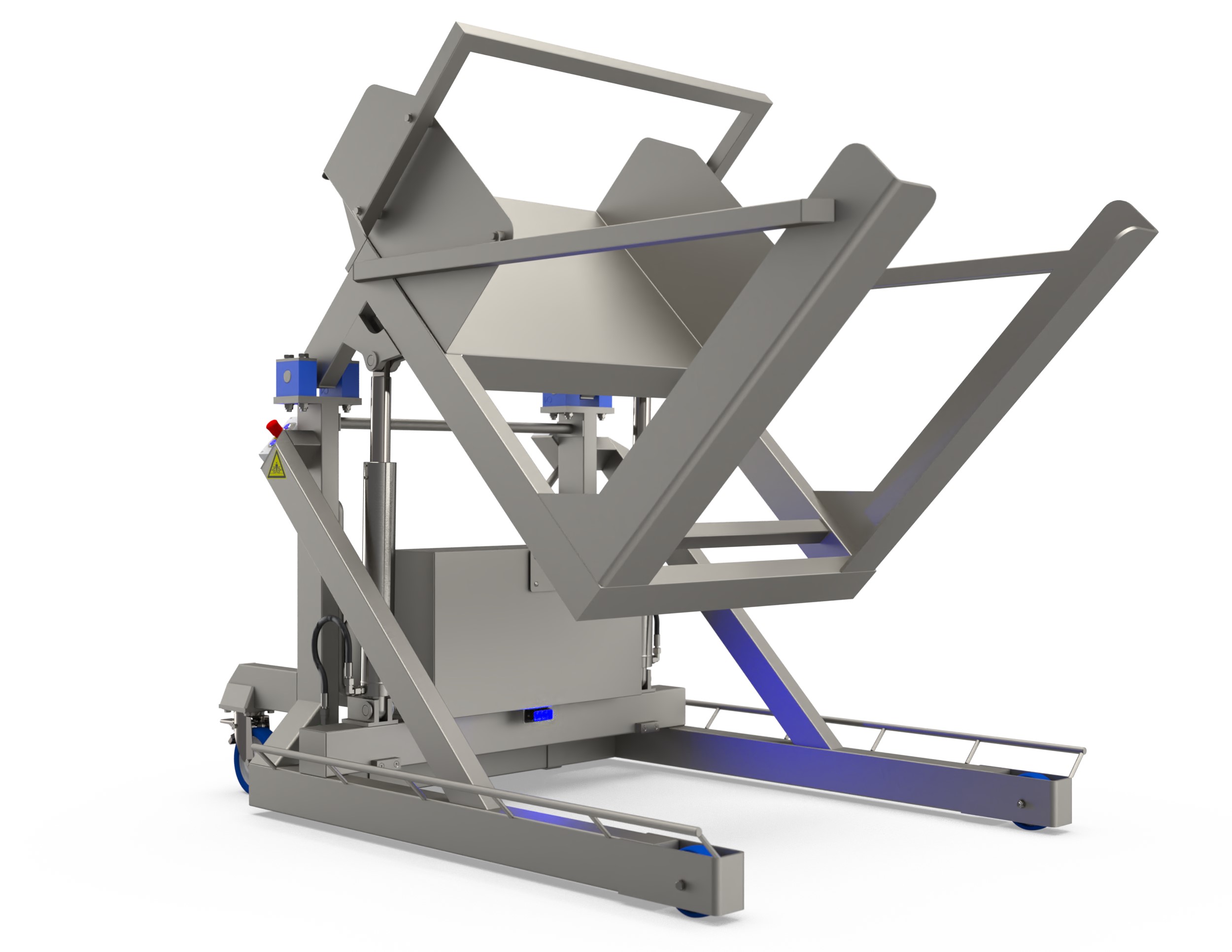

Nimo-KG SK 800 MK2 Double column lift

Beschreibung

Overview

The SK 800 MK2 lifting and tipping device, commonly referred to as a twin column lift, is a versatile solution primarily used within the food industry. Its primary function is to elevate and tilt standard 600-liter EURO-containers, facilitating various processes such as forming, filling, grinding, mixing, and more. This adaptable twin column lift can also be tailored to accommodate barrels, different large containers, or other specific industrial applications, extending its utility to sectors like chemicals, pharmaceuticals, and engineering workshops.

Designed with meticulous attention to ergonomic principles, the twin column lift prioritizes operator safety while enhancing overall production efficiency. Its ergonomic features minimize the risk of personnel injury, aligning with industry standards and best practices.

Design and function

The twin column lift comprises two main components: the main stand and the lifting frame. The stand consists of two columns constructed from plates and fully welded single hollow sections. The bottom frame is equipped with four feet for securing the machine to the floor. The lifting frame is primarily constructed from fully welded single hollow sections and moves within the columns. Vertical motion is achieved through an electro-mechanical system using either a roller chain or belt.

To ensure safety, the container to be tipped is positioned within the lifting frame, which features a retaining mechanism to secure the container in place. The twin column lift is driven by an electric gearbox motor with a brake. Operation is controlled via electrical push buttons, including an emergency stop button. The tipping process begins when the upper follower rollers of the lifting frame engage with the tipping curves, while simultaneously, the lower rollers continue to ascend within the columns.

For safety measures, the machine is equipped with a safety cage featuring electrically interlocked doors to prevent accidents.

General Points

The twin column lift is designed in accordance with the specifications of food industry authorities and complies with CE norms: 2006/42/EC, 2006/95/EC, and 2004/108/EC, as confirmed in the declaration of conformity enclosed in the CE documentation.

The twin column lift can be supplied in various standard designs at an additional cost:

- Low-built model (SK 800 MK-L)

- Mobile on wheels or able to move sideways on a rail (SK 800 MK2-T)

- Equipped with a combined lifting frame for buggies

- Features a locking device for special containers or varying container heights

- Suitable for heavier loads (maximum 1500 kgs)

- Offers an individually designed chute

- For technical data and dimensions, please refer to separate manual sheets.

- Special offers are available upon request.

Technical Specifications

The key components of the twin column lift are expertly crafted from stainless steel (AISI 304, SS2333) that has undergone a thorough glass-bead blasting process. For stability, the bottom frame features four stainless steel feet (M20) that offer adjustable height (+25/-15 mm) and secure fastening to the floor using M16 bolts.

Ensuring safety during operation, the twin column lift is equipped with a protective cage that incorporates electrically interlocked doors, further reinforced by a spring-loaded locking mechanism for mechanical security.

Within the lift’s columns, the lifting frame glides smoothly on four high-density plastic wheels. The transmission system employs two 1″ Simplex roller chains constructed from robust steel (BS 228-1962, SMS 1613) or a belt. These chains are firmly attached to the lifting frame using stainless steel link components. (As an optional feature, both the chain and chain wheels can be manufactured from stainless steel.)

Safety features include electro-mechanical limit switches to halt vertical motion, along with a top-position safety switch. The control panel boasts electrical buttons for seamless up and down motion control, complete with an emergency stop function.

Specifications:

- Motor Type: 90

- Power: 1.5 kW

- Speed: 1400 rpm

- Gear Design: Foot B3

- Voltage / Control Voltage: 400/230 V, 50 Hz / AC 24 V, 50 Hz

- Braking Torque: 25 Nm

- Lifting Speed: 7.1 m/min

- Operating Orientation: Right (left-hand design available as an option)

- Maximum Lifting Capacity: 800 kg

Adresse

Backsaver / Van Oirschot Group

Kruisbroeksestraat 17

5281 RV Boxtel

Netherlands

Telefon+31 411 689 372

Fax+31 411 684 725