Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

GAROS

Über uns

GAROS is a trusted name in the global meat processing industry, with origins deeply rooted in the meat industry and with over 90 years of experience. Garos was founded 40 years ago, we have specialized in designing and manufacturing innovative machinery for meat, poultry, and fish processing, delivering customized solutions for businesses of all sizes.

GAROS is a trusted name in the global meat processing industry, with origins deeply rooted in a family business founded over 90 years ago. For the past 40 years, we have specialized in designing and manufacturing innovative machinery for meat, poultry, and fish processing, delivering customized solutions for businesses of all sizes.

With a commitment to precision engineering and a relentless pursuit of innovation, our machines are known for their reliability, efficiency, and exceptional performance. Our extensive product range includes injectors, tumblers, trolley tumblers, brine preparation system, roller tenderizers, vacuum filling solutions, and complete automated production lines, all designed to optimize production processes while maintaining the highest hygiene standards.

GAROS is headquartered in Jönköping, Sweden, where we focus on research, development, and engineering. We also operate a key manufacturing facility in Poland, strategically located in the heart of Europe to ensure fast logistics and timely deliveries to our global customers.

As a family-run business, now led by the third generations of the Gustafson family, we combine traditional values with cutting-edge technology. Over the years, we have built a strong network of international partners, ensuring local support and expertise in over 30 countries.

Our mission is to support the evolving needs of the meat processing industry with machines and solutions that enhance productivity, sustainability, and product quality. From initial consultation to final implementation, we offer comprehensive service and support at every stage of the process.

At GAROS, we believe in pushing boundaries to shape the future of food processing. Our dedication to innovation and customer satisfaction has earned us a reputation as a trusted partner in the industry.

Discover the GAROS difference – where advanced technology meets reliability and exceptional service.

Unsere Produktgruppen

Downloads

Dokumente

Keywords

- Meat processing machinery

- Tumblers

- Injectors

- Automated production lines

- Defrosting Solutions

Unsere Produkte

GAROS MDF Tumbler – Multi Displacement Flight Tumbler

The GAROS MDF Tumbler is an advanced vacuum solution designed for optimal tumbling, marinating, and mixing of meat, poultry, and fish products. Engineered for high efficiency and superior product movement, the MDF Series ensures maximum protein activation, improved moisture retention, and uniform brine absorption, delivering exceptional product quality with every batch.

Key Features of the GAROS MDF Tumbler:

Multi Displacement Flight (MDF) System – Unique flights create a four-way product movement, ensuring a gentle yet highly efficient massaging process.

▶️ High Capacity & Flexibility – Available in models ranging from 1,600L to 10,000L, adaptable to various production needs.

▶️ Vacuum Technology for Enhanced Yield – Maintains optimal protein extraction and moisture retention.

▶️ Cooling & Heating Jacket – Efficient temperature control via glycol-cooled or heated double jackets, supporting thawing, defrosting, or cooling operations.

▶️ Automated Control System – Intuitive touch-screen interface allows for precise recipe management, variable drum speed control, and cycle automation.

▶️ Hydraulic Tilting System – Ensures easy product discharge and thorough cleaning, reducing downtime and increasing efficiency.

▶️ Hygienic & Durable Construction – Made of high-quality stainless steel, designed for fast and easy sanitation with minimal maintenance.

Why Choose GAROS?

With over 40 years of expertise in meat processing technology, GAROS is a trusted global leader in tumbling solutions. The MDF Tumbler is engineered to meet the highest industry standards, offering superior product consistency, operational efficiency, and ease of use.

Whether you need a solution for tumbling, marinating, or defrosting, the GAROS MDF Tumbler delivers exceptional results, batch after batch.

🔹 GAROS – Perfect Tumbling for Premium Quality. 🔹

GAROS GBT Trolley Tumbler

The GAROS GBT Trolley Tumbler is an innovative and highly efficient solution for tumbling, mixing, coating, and marinating a wide range of products, including meat, poultry, fish, ready meals, vegetables, and salads. Designed to provide gentle yet thorough product movement, the GBT Series ensures minimal product damage while maximizing brine absorption, marinade distribution, and overall yield improvement.

Key Features of the GAROS GBT Trolley Tumbler:

▶️ Gentle & Efficient Mixing – Utilizes 200L Eurobin trolleys for a controlled process without paddles or mixing arms, ensuring product integrity.

▶️ High Capacity & Flexibility – Available in GBT 300 and GBT 600 models, handling up to 200kg per cycle, perfect for both small and large production needs.

▶️ Superior Product Movement – the design of the GBT enhances product flow and uniform mixing with each drum revolution.

▶️ Vacuum Functionality – Capable of reaching up to 50% vacuum, improving marinade penetration and moisture retention.

▶️ Customizable Mixing Programs – Stores up to 20 programmable recipes, allowing for precise control of mixing cycles.

▶️ Optional Mixing Forks – Increases processing versatility, making it ideal for more complex or delicate products.

▶️ Hygienic & Easy to Clean – Stainless steel construction with a smooth, easy-to-clean design, ensuring high sanitation standards.

▶️ User-Friendly Control Panel – Simple touch-screen operation for easy recipe management and process optimization.

Why Choose GAROS?

With over 40 years of experience in meat processing technology, GAROS is a global leader in tumbling and marinating solutions. The GBT Trolley Tumbler is specifically engineered to enhance efficiency, reduce labor time, and deliver consistent, high-quality results.

Whether you’re processing meat, poultry, seafood, ready meals, or plant-based products, the GAROS GBT Trolley Tumbler provides exceptional performance, versatility, and ease of use.

🔹 GAROS – Precision Tumbling for Superior Quality. 🔹

GAROS Brine Preparation System – GLB & GLT Series

The GAROS Brine Preparation System, consisting of the GLB Brine Mixer and GLT Storage Tank, is designed for precise, automated preparation and storage of brine used in meat, poultry, and fish processing. Engineered for high efficiency, hygiene, and consistency, this system ensures optimal ingredient dispersion, homogeneity, and temperature control, making it an essential component for injection, tumbling, and marination processes.

Key Features of the GAROS Brine Preparation System (GLB & GLT):

▶️ GLB Brine Mixer – High-Efficiency Mixing & Dispersion

- Available in 500L, 1000L, 1500L, and 2000L capacities

- Powerful high-shear pump ensures rapid and even brine mixing

- Spring-supported feed hopper with pneumatic vibrator prevents ingredient bridging

- Automated level sensors for precise ingredient control

- Cooling jacket for maintaining ideal brine temperature

- Automatic washing system for easy cleaning and sanitation

▶️ GLT Storage Tank – Hygienic Brine Holding & Distribution

- Available in 1000L, 1500L, 2000L, and 3000L capacities

- Conical-shaped base ensures 100% brine utilization

- Integrated cooling system maintains stable brine temperature

- Fully stainless steel (316 acid-resistant) construction for durability and hygiene

- Automated pumping system for efficient brine transfer to injectors, tumblers, and marinators

▶️ Seamless Integration with GAROS Processing Equipment

- Direct connection to GAROS Injectors (GSI Series), Tumblers (MDF & GTB Series), and Vacuum Filling Systems (VFS)

- Supports automated, continuous production workflows

- Ensures consistent brine quality and optimal product yield

Why Choose GAROS?

With over 40 years of experience in meat processing technology, GAROS Brine Preparation Systems provide unmatched precision, automation, and hygiene standards for industrial food production. The GLB & GLT Series help manufacturers optimize brine efficiency, reduce waste, and enhance product consistency across all processing stages.

Whether you need small-scale or high-capacity brine preparation, the GAROS Brine Preparation System delivers reliable, high-performance solutions tailored to your needs.

🔹 GAROS – Precision Brine Preparation for Superior Processing. 🔹

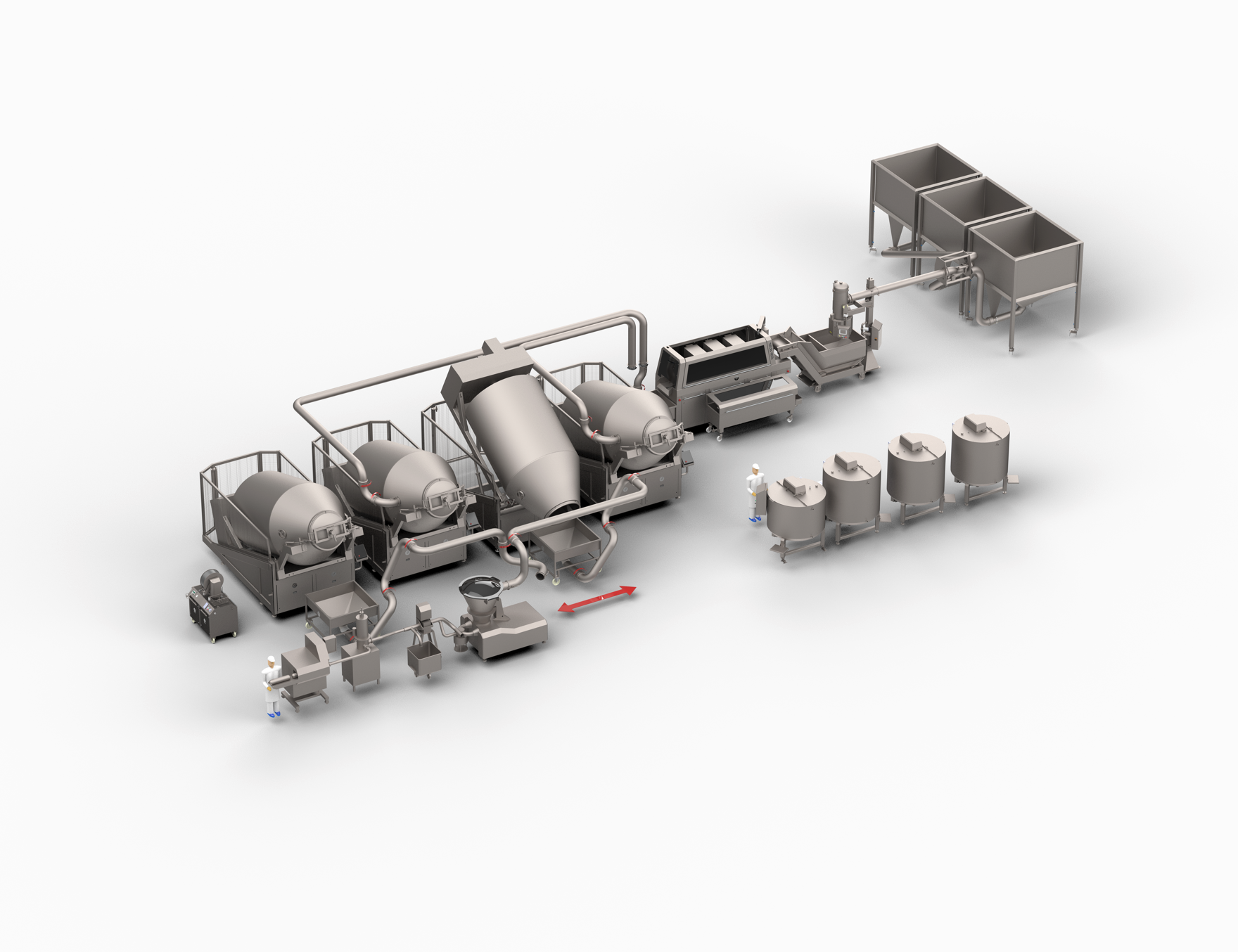

GAROS Automated Production Lines with Vacuum Filling System (VFS)

The GAROS Automated Production Lines are designed to streamline meat, poultry, and fish processing, integrating advanced vacuum filling, brine preparation, tenderizing, injecting, tumbling, and mixing technologies into a single, high-efficiency production flow. At the heart of this system is the GAROS Vacuum Filling System (VFS), which ensures precise, continuous product transport, optimizing production speed, consistency, and hygiene.

Key Features of GAROS Automated Production Lines with VFS:

▶️ Seamless Process Integration – Customizable end-to-end solutions integrating whole production line - from brine preparation to the transport to the packing and portioning area.

▶️ Vacuum Filling System (VFS) – Enables gentle, continuous product transport, preventing product damage while ensuring optimal filling accuracy.

▶️ Vacuum Metering System (VMS) – Precisely doses boneless and semi-boneless products to ensure consistent portioning and batch control.

▶️ Automated Brine Injection – Synchronized with GAROS Injectors (GSI Series) for highly efficient brine distribution across various product types.

▶️ Integrated Tumbling & Marinating – GAROS MDF Tumblers work with VFS to enhance product texture and quality.

▶️ Customizable Configurations – Adaptable to various production scales, from small-batch processing to fully industrial automated lines.

▶️ High Hygiene Standards – High Hygiene Standards – Stainless steel construction, easy-to-clean components, and automated Garos Preassure Cleaner

▶️ Smart Control & Monitoring – Centralized touch-screen interface for real-time process control, automation, and recipe storage.

Why Choose GAROS?

With over 40 years of expertise in meat processing technology, GAROS Automated Production Lines offer a state-of-the-art solution for food manufacturers seeking higher efficiency, precision, and quality control. The VFS system is an essential component, ensuring that products are processed gently yet efficiently, maintaining texture, yield, and hygiene at every step.

Whether you’re looking to automate your processes, GAROS production lines provide the scalability, customization, and performance needed to stay ahead in the modern food industry.

🔹 GAROS – Automated Lines for Unmatched Food Processing Performance. 🔹

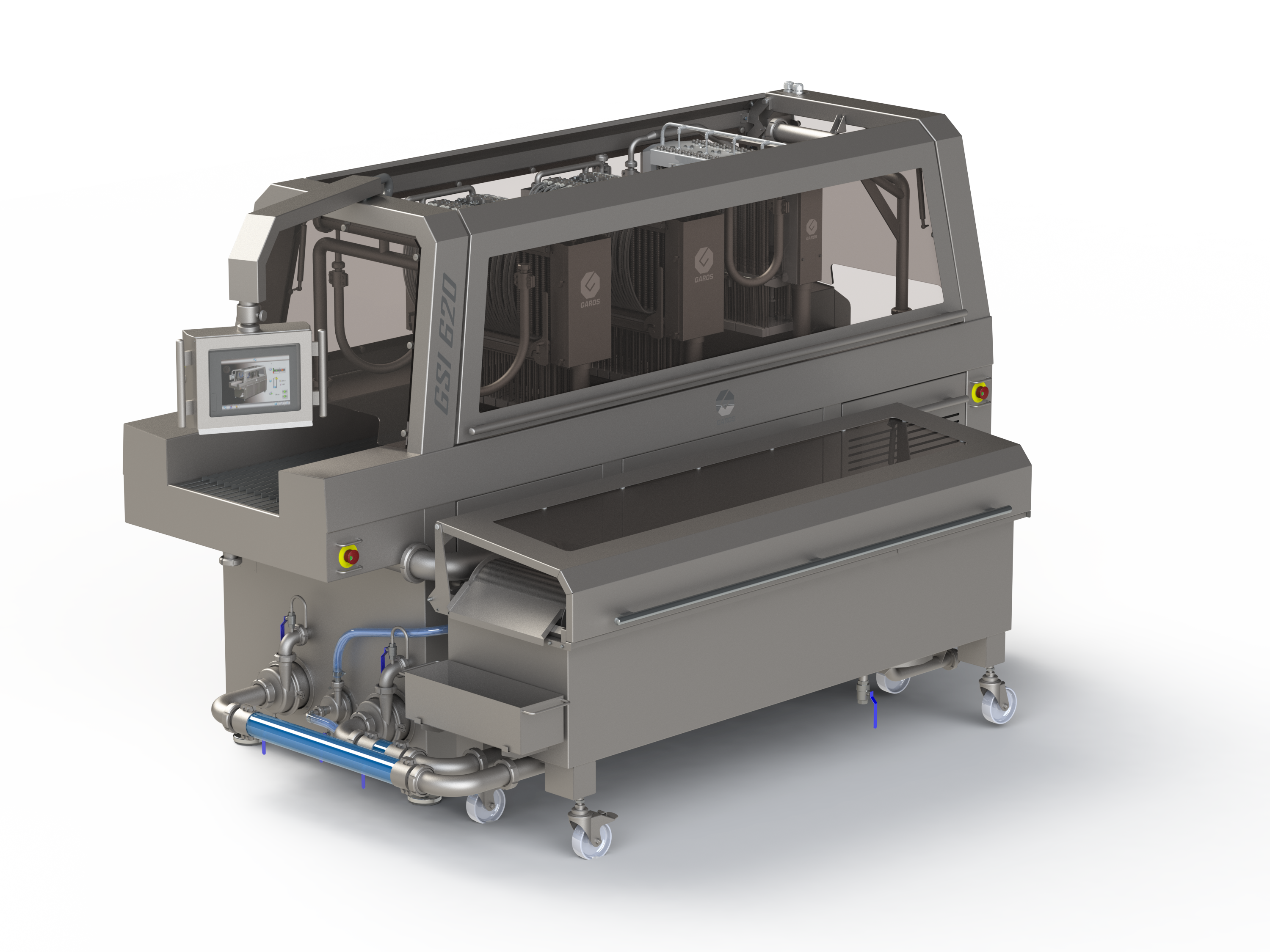

Garos GSI Injector

The GAROS Brine Injector (GSI Series) is an advanced solution for precise and efficient injection of brine and marinades into meat, poultry, and fish products. Designed with cutting-edge technology, the GSI Series ensures uniform distribution of brine while maintaining the highest levels of hygiene and production efficiency. Whether processing bone-in or boneless products, GAROS injectors provide superior injection consistency, helping to enhance the product quality.

Key Features of the GAROS GSI Brine Injector:

▶️ Versatile Application – Ideal for red meat, poultry, and fish, available in configurations for both bone-in and boneless products.

▶️ Optimized Injection System – Up to 1,968 precision needles, ensuring even brine distribution for better product quality.

▶️ Customizable Injection Levels – Adjustable brine injection percentage to meet specific production needs.

▶️ Advanced Needle Design – needles that reduce damage to delicate products, ensuring high-quality results.

▶️ Inline Filtration System – Continuous filtration prevents needle clogging and ensures consistent injection performance.

▶️ Hygienic and Easy to Clean – Fully stainless steel construction with automatic cleaning and sanitation features.

▶️ Automated Control System – Intuitive touch-screen panel for easy operation, recipe storage, and process optimization.

Why Choose GAROS?

With over 40 years of experience in meat processing technology, GAROS is a global leader in providing high-performance brine injectors that improve efficiency, yield, and product consistency. Our GSI Series injectors are designed to integrate seamlessly into automated production lines, making them the preferred choice for food processing companies worldwide.

Whether you need a high-capacity system for industrial production or a versatile injector for smaller-scale operations, GAROS Brine Injectors deliver unmatched performance, precision, and reliability.

🔹 GAROS – Precision Injection, Superior Results.🔹