Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

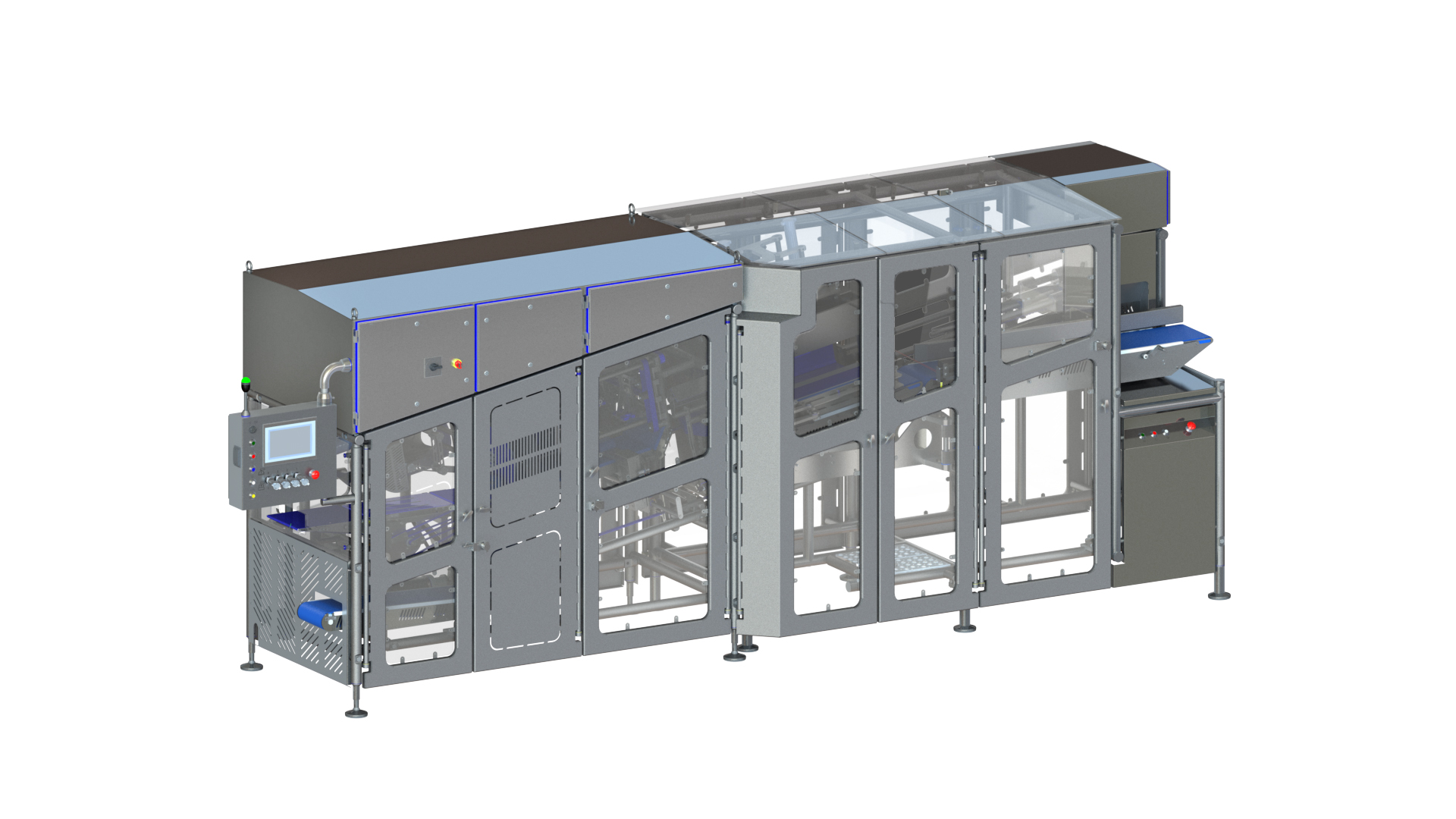

IBS 4600 Precooked Bacon Slicer

IBS 4600 Precooked Bacon Slicer

Beschreibung

The Thurne IBS4600 has established itself as the industry frontrunner slicing solution for precooked bacon processing. Four independent feeds, four independent blades, four independent cameras, combined with Thurne vision technology has forged a bacon processing revolution known the world over.

IBS4600 is the world’s first slicer to have 4 independent feeds, each with its own vision system that gives weight control of individual slices, regardless of belly size. High yields with low giveaway are the norm thanks to the precision and control that delivers constant weight portions with remarkable consistency. End user and consumer appeal is enhanced because the end product has a uniform appearance, texture and quality and can be sorted into fixed weight /fixed count packs.

Undercooking is completely eliminated further enhancing accuracy of finished, cooked slice weight. Likewise, over packing is eliminated, giveaway is greatly reduced and an extremely good return on investment is realized.

Features & Benefits

- Users are experiencing double digit percentage increases in raw slices per pound

- Achieves in excess of 7% more Grade 1 cooked slices

- High pack weight accuracy with extremely low giveaway

- Low maintenance cost

- Fast ROI

- Interface with microwave oven for consistent cooked weights

- Available for 3 lane and 4 lane operation