Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

Thurne-Middleby LTD

Beschreibung

The Thurne PolySlicer 1000 offers versatility, slicing accuracy and high throughput. The slicer is the ideal choice for processors who require a compact, versatile and easy to use machine with a large slicing aperture for efficient multi-log slicing of stacks, shingles or wafer-thin slice packs.

- High speed involute or orbital blade option

- High performance involute blade running at up to 1500 rev/min

- Orbital blade for delicate or large products running at up 600 rev/min

- Product retraction eliminates sliver slices

- Variety of pack presentation formats

- Compact footprint

- Optional Interleaver can be retrofitted

- Optional Variety Conveyor can be retrofitted

- Optional Stacker for tall stacks <100mm

Interleaver Option

- Independent cutting of paper and of product

- Optimisation of the product blade for the application and increased blade life

- Twin lane operation running at up to 700rpm

- Can interleave single slices within a shingle or stack (<80mm) and/or insert a sheet under complete groups (underleave)

- Controllable paper positioning for excellent presentation

- Easy access for quick reel change and cleaning

- Available for retrofit at a later stage

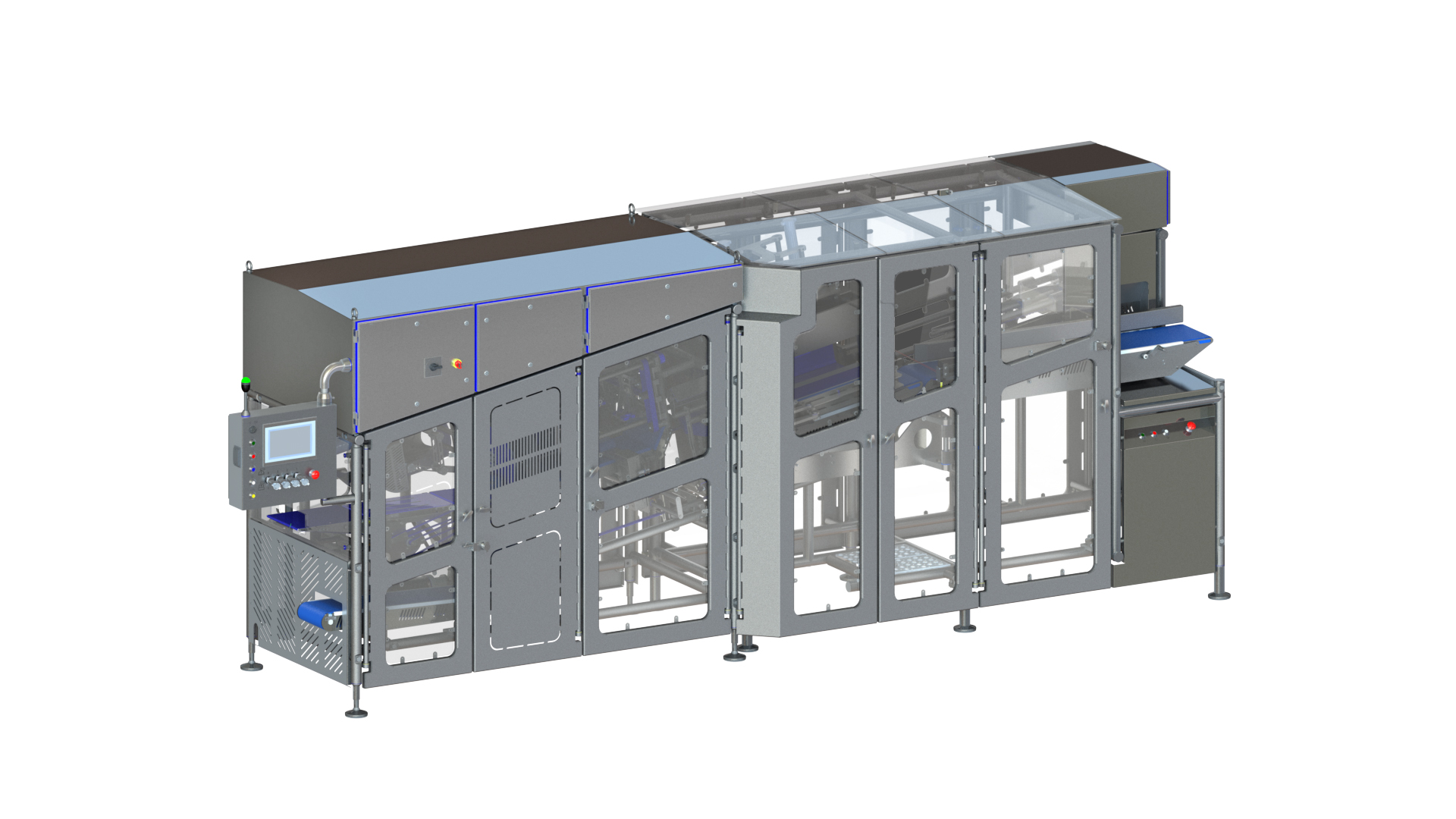

Fully Integrated Slicing Systems

Thurne supplies fully integrated slicing and packing lines for cooked and cured meat packs.

You benefit from:

- A safe, balanced and effective line

- Maximum performance

- Single source supply and support

- Simplified line certification