Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

VR - Vision Inspection System

Beschreibung

The VR - Vision Inspection Sytem offers the ultimate in safeguarding for brand and consumer protection.

Directly after the packs have been labelled by the Nobac 5000 linerless applicator, the VR will then identify errors and reject any packs where faulty labels are detected. The VR does this by optical vision inspection. These faults are largely due to poor quality print and inaccuracies, but the VR analyses even further and will check for label position, quantity and orientation for guaranteed consistency across all packs. Moreover, even small print such as barcodes, use-by dates and traceability codes are also inspected. In fact, all printed information.

Collectively, the process offers complete peace of mind, alleviating the need for manual analysis which can lead to faults going unchecked.

VXR USPs

- Total inspection incorporated into just 1.9m.

- Avoid damaging press coverage and extortionate costs resulting from recalls.

- Eliminate human error.

- Increase production times.

- Reject confirmation and bin full as standard for vision and x-ray rejects.

- High speed user-friendly interface for rugged factory environments.

- Pack images and pack quality information can be stored and retrieved using an open communication protocol.

X-ray

- Heightened sensitivity for detecting dense mass / contaminants.

- Identifies foreign bodies such as glass, metal, ceramics and bone.

- Identifies contaminants through printed film, coloured trays and aluminium trays.

- Locates the correct position of the product in the tray.

- Number of products in a tray i.e. meatballs / burgers.

Vision

- Identifies and rejects errors, enabling operator-free

end of line automation. - Automatically detects faulty labels: printing errors

and poor quality print. - Analyses multiple label positions, quality and orientation.

- Checks all printed information: bar codes, use-by

dates and traceability codes.

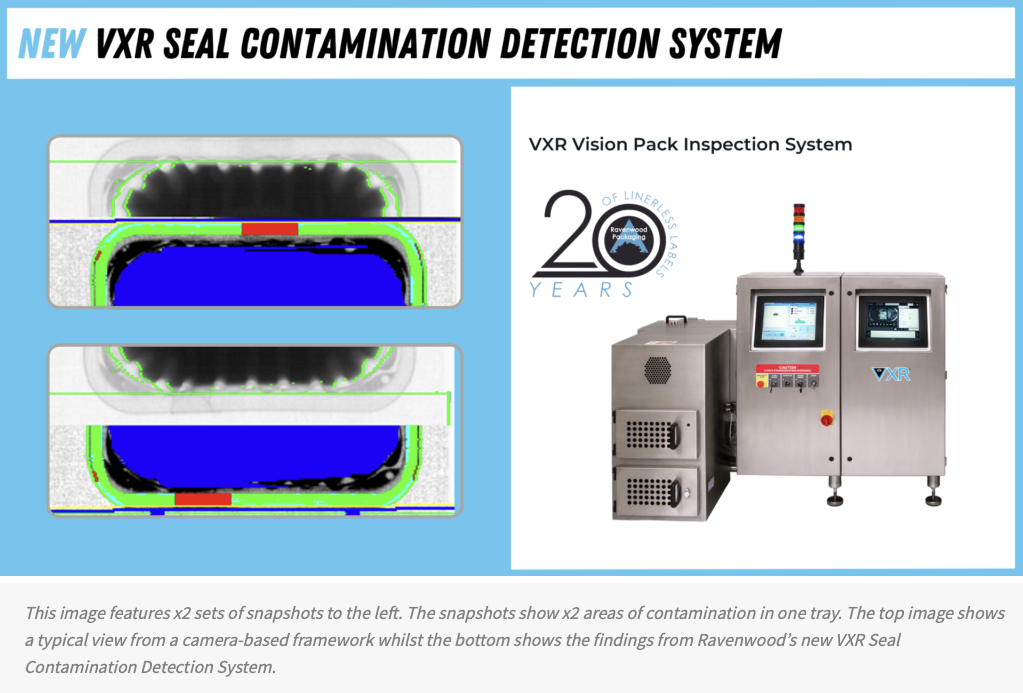

Seal Contamination Detection

- Detects for contaminants in the seal including foods that have ‘slipped’.

- X-ray functionality must be incorporated for seal inspection.

Deep Learning

OCR solution – based on established industrial grade software.

- New module for adding to the Vision Application on the VR and VXR machines.

- Module uses Deep Learning to analyse the characters in the field of interest.

- Choice of pre-learned character sets available to rapidly decode many characters.

- Set up of the Deep Learning OCR field is similar to the conventional set up in the new or edit product screens.

- Does not require the font to be taught as is the case with conventional OCR for new fonts.

- Conventional OCR remains available in the app.

- New version requires an additional licence and USB dongle to be installed.

- Also available on new order machines as part of the machine build.

Anti-Reflection

- Software minimises glare and reflections on flow wrap packs.

- Improved image processing combined with enhanced illumination.

- Retrofittable into existing Vision systems.

- Supplied as an optional extra on new machine orders.

- Standard packs can still be inspected as usual.

Adresse

Ravenwood Packaging Ltd.

Unit 1 Brunel Business Court, Eastern Way

Bury St. Edmunds

IP32 7AJ

Great Britain and Northern Ireland

Telefon+44 1284 749144