Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

Beschreibung

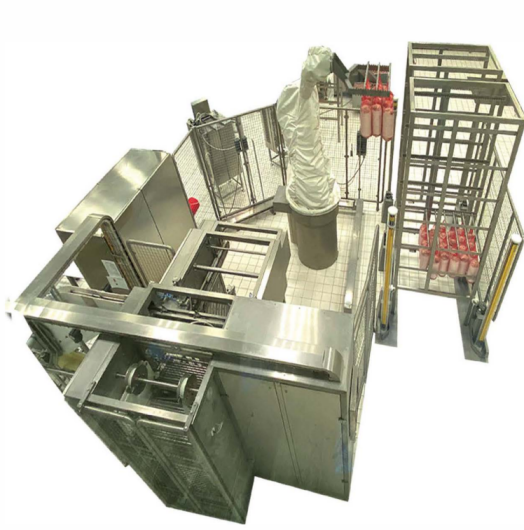

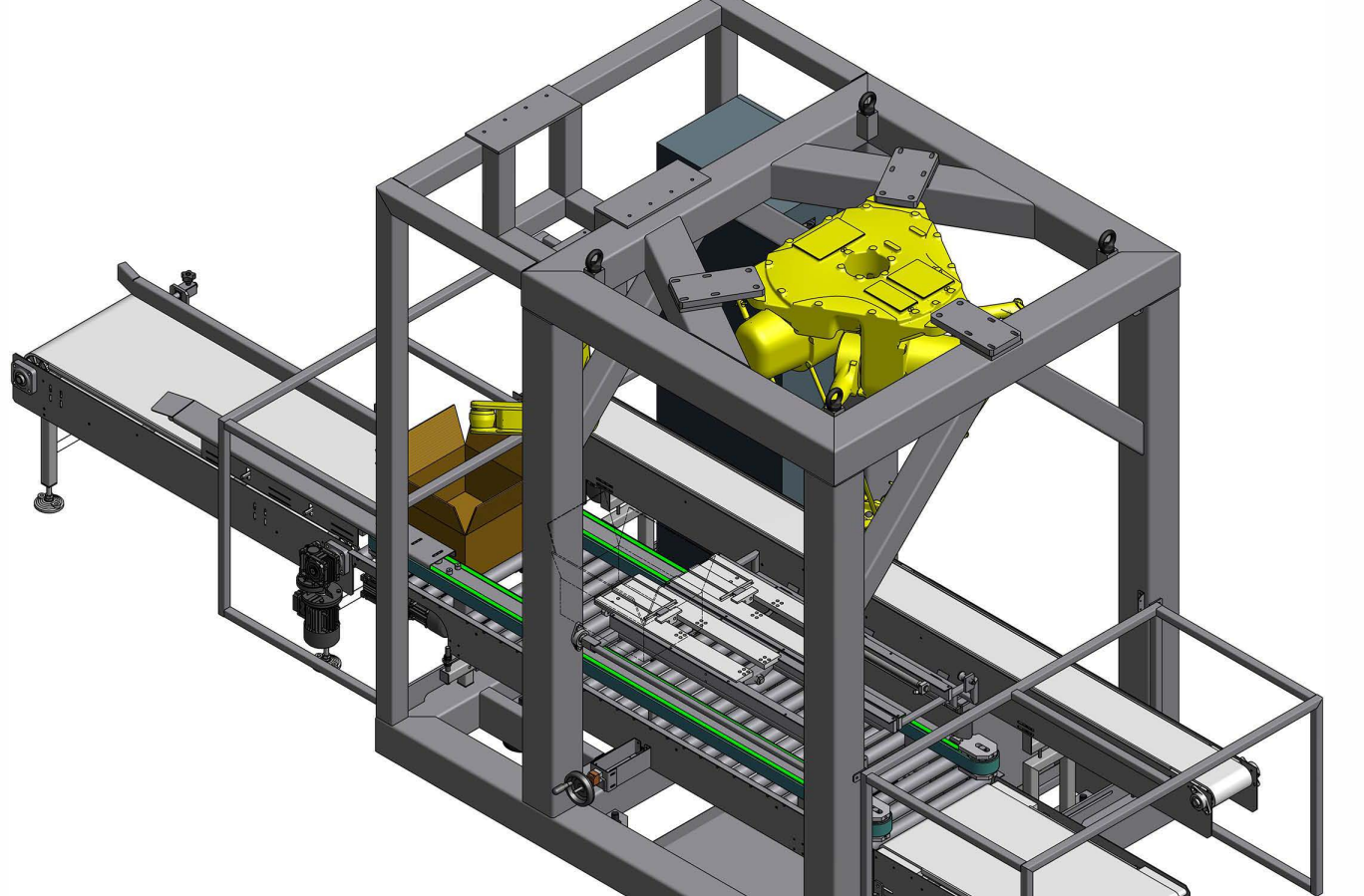

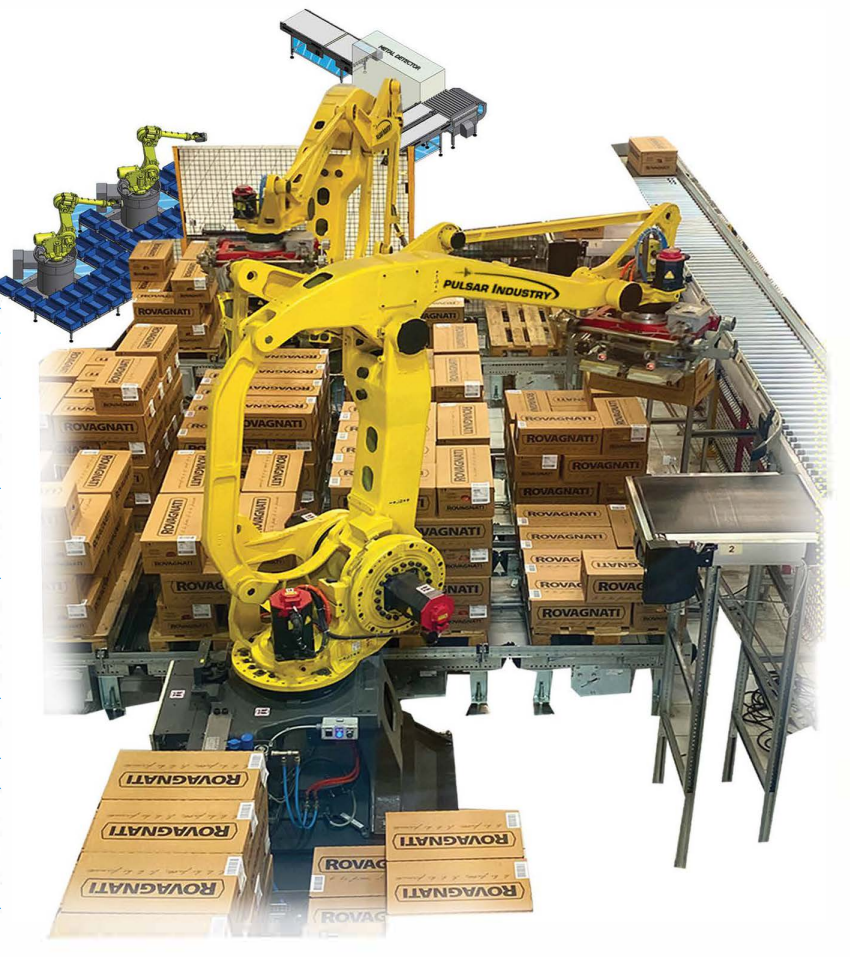

For the seasoning of products Pulsar Industry has developed an automatic system with anthropomorphic robots that that carry out the arrangement in bars and the subsequent composition of loading units intended for storage in the maturing cells. The system includes the management of all the

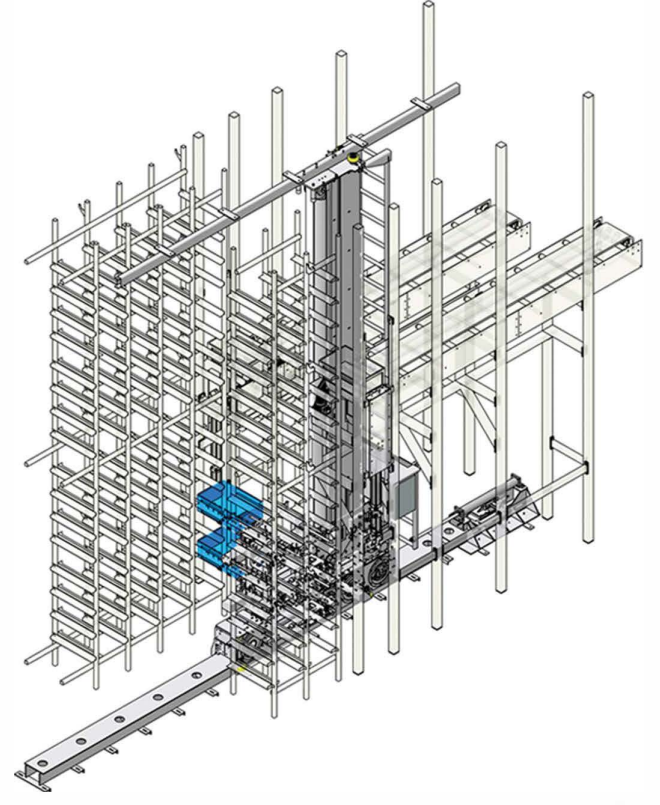

cell control parameters and the final handling, assisted by automatically guided stainless steel shuttles

and anthropomorphic robots, to the packaging lines or slicing lines. This systemfully integrated allows the weight loss to be monitored daily in all cells thanks to the ability of the shuttles to weigh automatically each individual individual load unit, thus providing this way the most complete control of levels of seasoning and quality of the product. It is also possible to carry out integrated analyses of consumption of labour, energy

and other industrial costs, of machine downtime for each work cycle and production efficiency based on the calculation of OEE (Overall Equipment Effectiveness).