Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

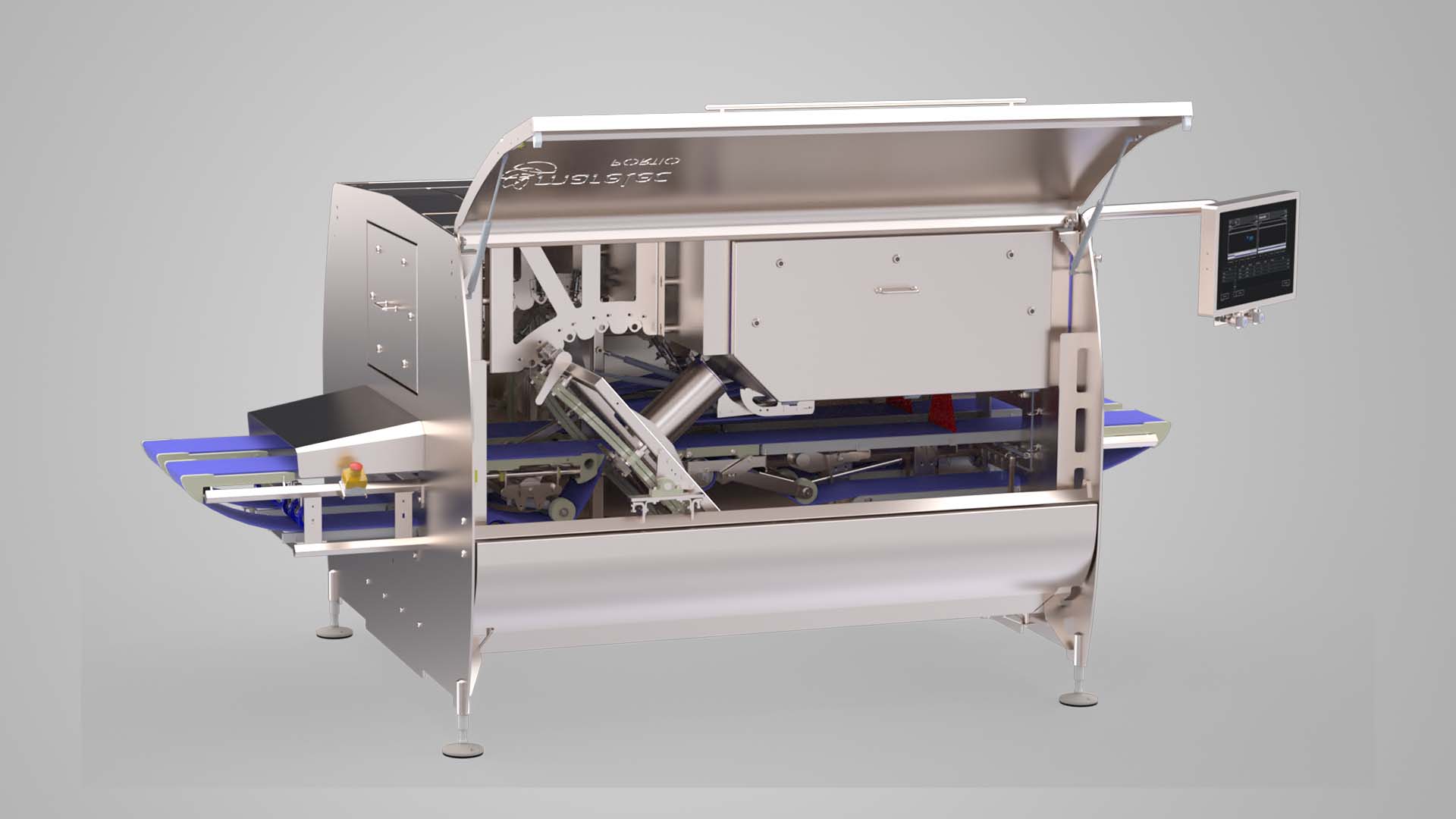

Intelligent Waterjet Cutter PORTIO JET

Description

MAXIMIZING YIELDS WHEN CUTTING POULTRY FILLETS OR DEBONED LEG MEAT INTO PREDETERMINED SHAPES OF FIXED WEIGHT WITH THE MARELEC PORTIO JET.

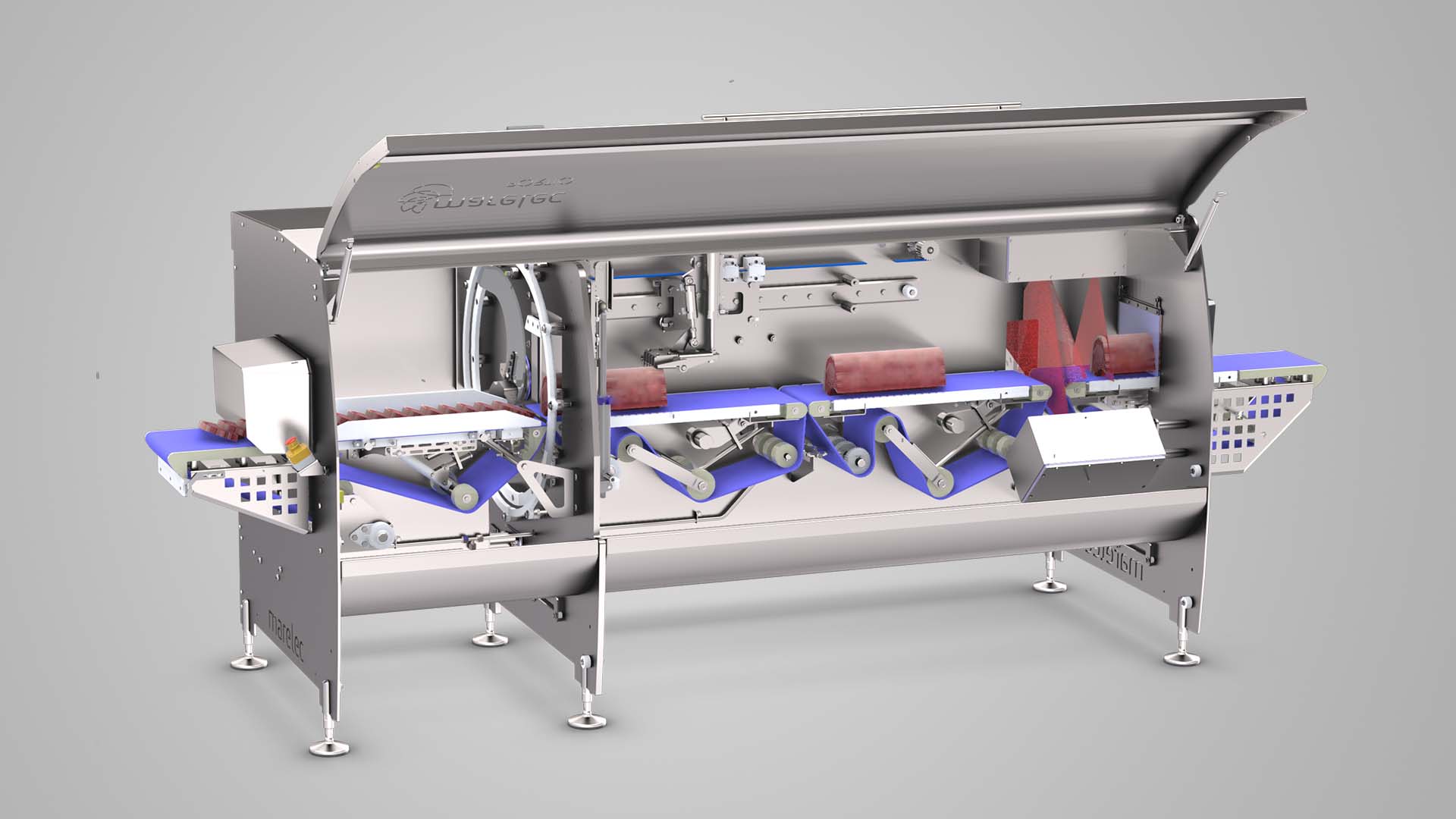

The MARELEC PORTIO JET is a state of the art waterjet cutter based on more than 15 years successful experience in portioning. The waterjet cutter is designed to portion boneless poultry products such as chicken breast and boneless leg meat into predetermined customized shapes while maintaining fixed weights.

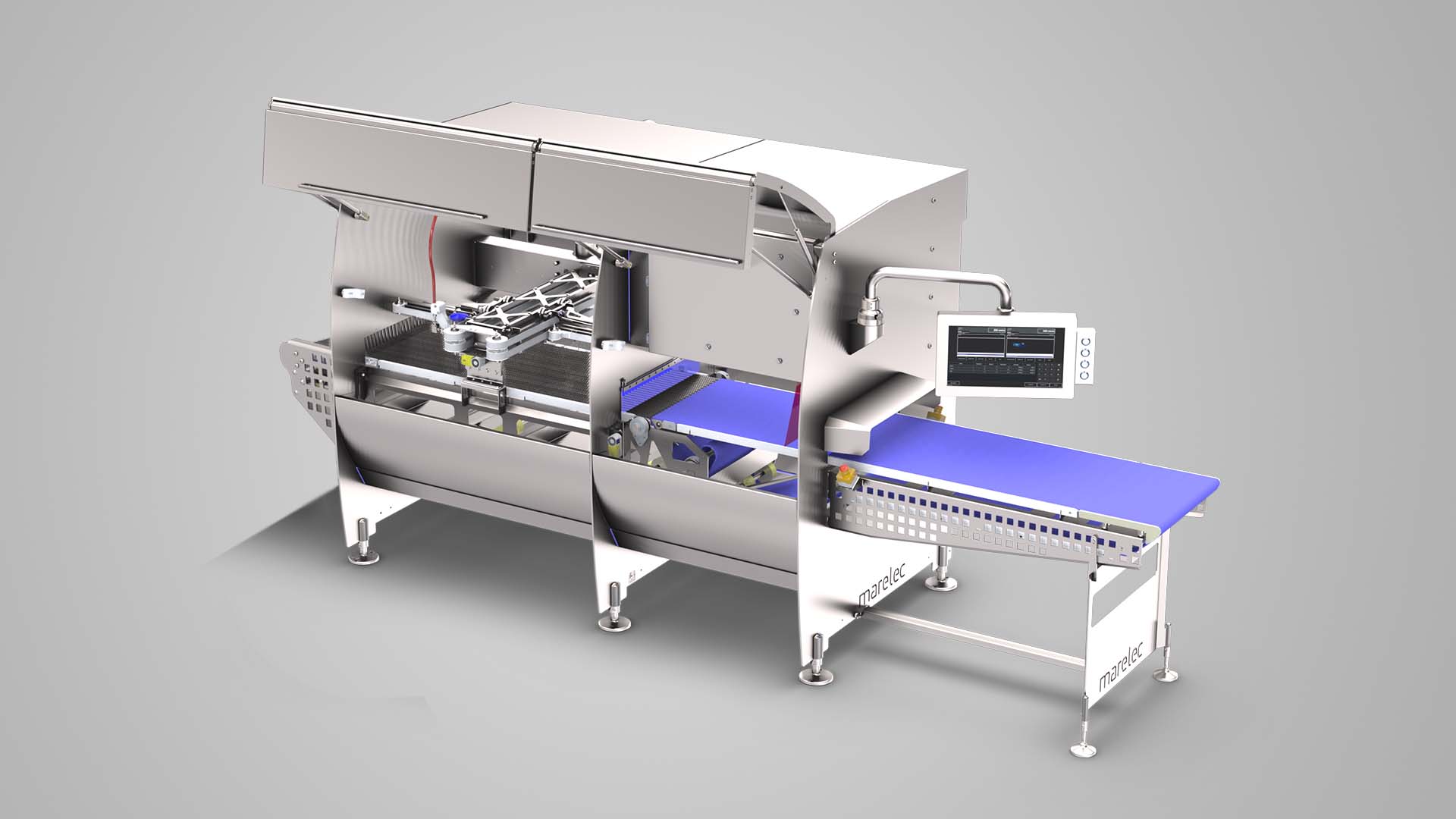

The PORTIO JET has been developed to maximize yields when cutting poultry fillets or deboned leg meat into predetermined shapes of fixed weight. The camera/laser combination scans to the highest accuracy, before the intelligent cutting algorithm calculates the optimal cutting pattern.

There is a list of predetermined cutting patterns programmed, from which parameters such as weight and size of the portions can be adapted. There is also a mode where the cutting pattern can be drawn on a scanned product to define specs.

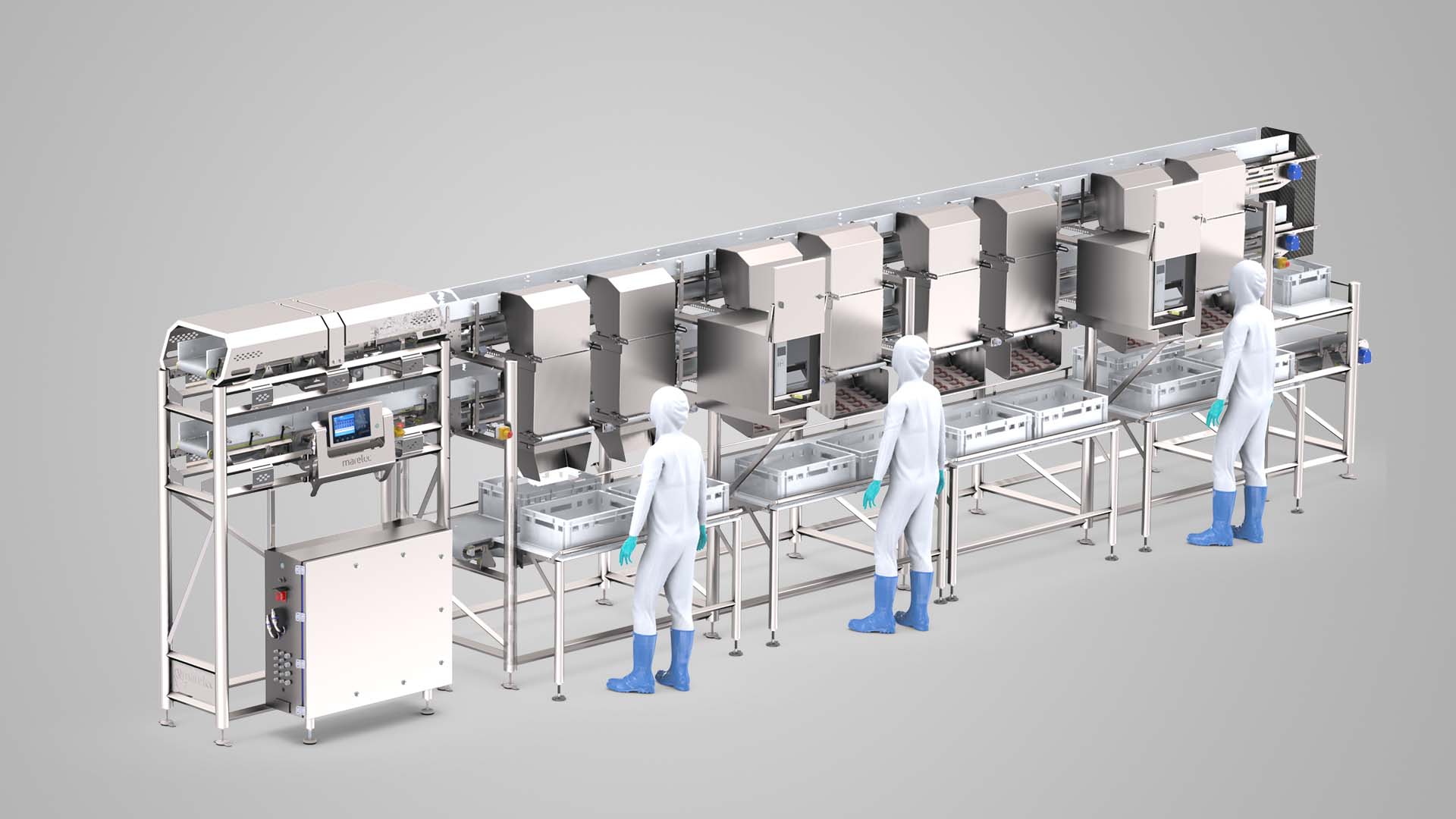

Over 300 programs can be stored with a customized name, making it possible to switch cutting patterns within seconds. Multiple streams of products can be loaded next to each other on the 600mm/24” wide belt and work with multiple applications simultaneously.

Typical applications include cutting chicken fillets into fixed-weight portions, cubes or strips. Boneless leg meat can be trimmed down and portioned into fixed-weight portions, better known as steaks or thigh patty. Very popular patterns are strips or cubes, such as karaage, kakugiri or BLK.

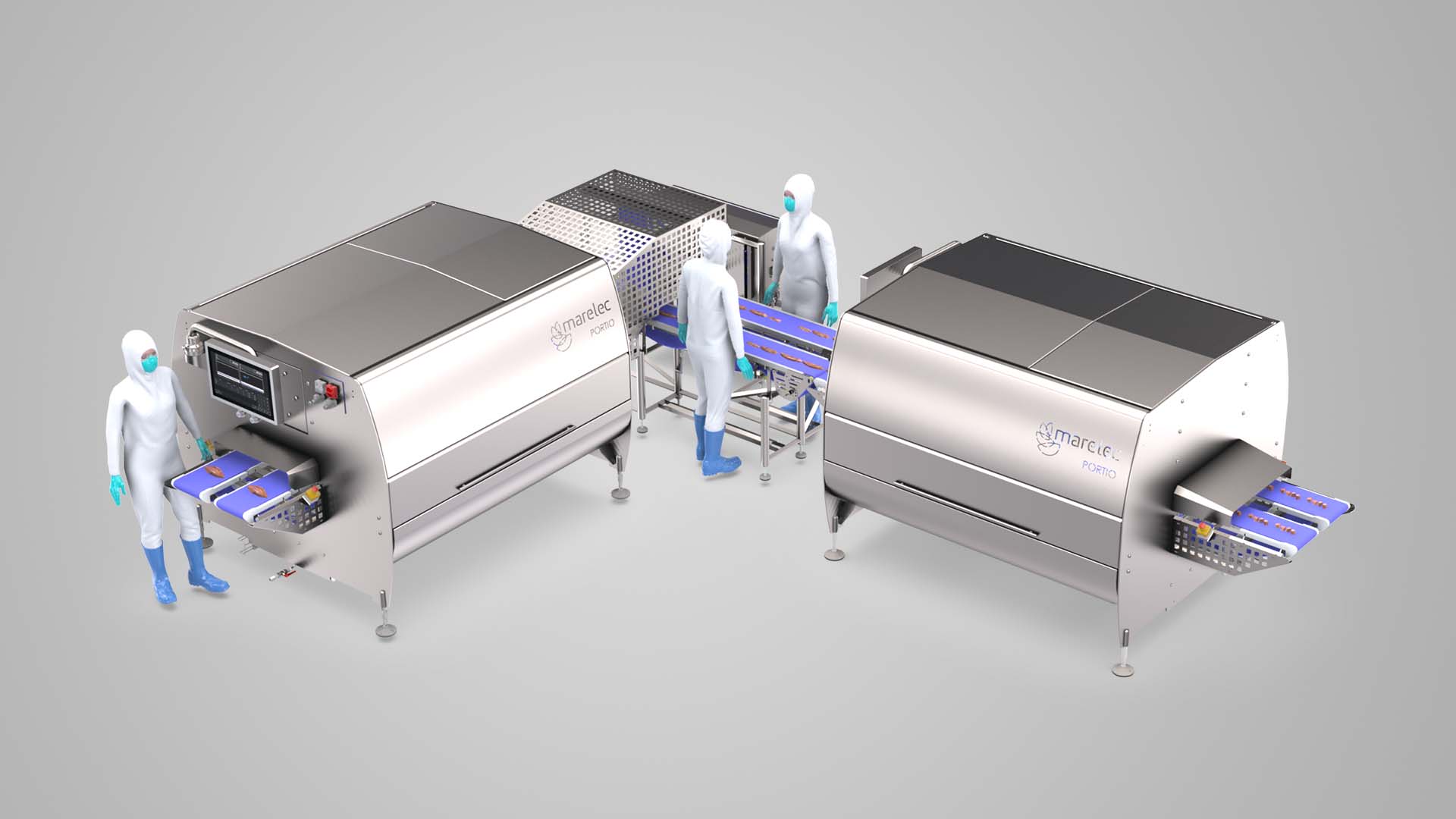

The PORTIO JET is built in a modular way. It starts with the base module, in which all electronics, scanning and HMI are integrated. As standard, this base unit controls a module with two cutting stations. This combination is called PORTIO JET 2.

The standard unit can be extended into a series of modules, each with two high-pressure waterjet nozzles - up to four modules or eight stations in total. Thanks to the modular design, these extra stations can be added whenever your volumes require it.

The MATRIX J software collects all production data from the PORTIO JET, enabling it to generate production reports per shift or program and to trace changes at a machine level. MATRIX J software enables users to remotely create programs offline and monitor the machine status through an event log.

Address

MARELEC Food Technologies NV

Redanweg 15

8620 Nieuwpoort

Belgien

Telephone+32 58 22 21 11

Fax+32 58 23 92 80