Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

alco Product Preparation Line

Beschreibung

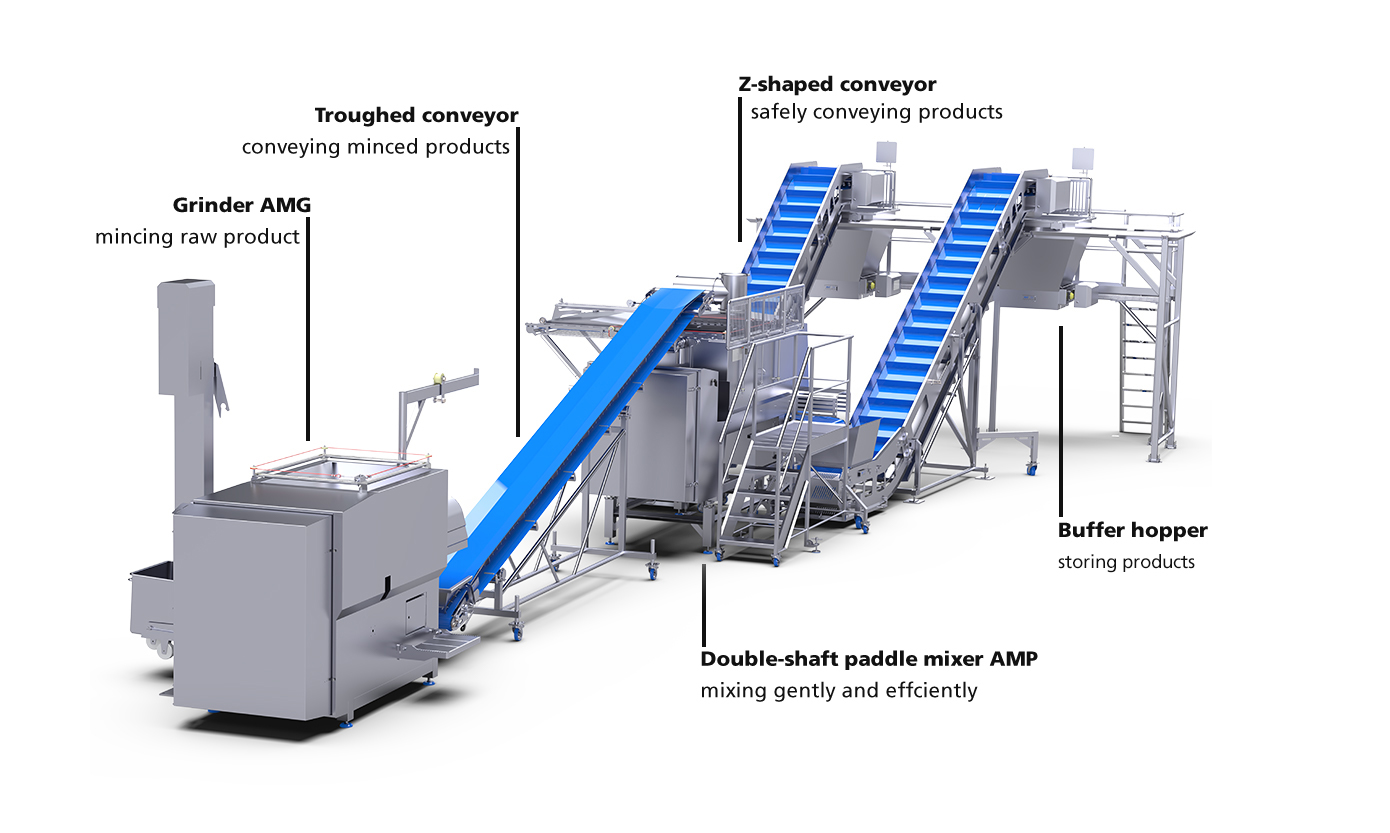

A high-performance product preparation line for the grinding and standardization of sausage meat and other homogeneous product masses for a wide range of end products can be individually configured from the meat grinders, conveyor systems and mixers offered by alco. alco meat grinders grind both fresh meat (up to 15 t/h up to Ø 3 mm) and frozen meat blocks at an hourly capacity of up to 6 t / h up to Ø 5 mm. At alco the top priorities are the absolute reliability of the systems, optimum cutting quality and high hygiene requirements. Ideal cutting results with maximum service life are achieved by means of multi-part cutting sets consisting of perforated disks, ring knives and pre-cutters combined with one another. The upstream twin-screw system consisting of feeding and working screw continuously conveys exactly the amount of raw material, which can also be removed from the cutting set, so that crushing of the material can be avoided. The gentle material supply ensures efficient cutting and preserves the quality of the meat. After grinding, the pre-ground products are automatically conveyed into the alco mixers by means of conveyor technology such as screws, conveyors or vertical conveyors. The conveyor line to the mixer can optionally also be used to analyse the composition of the product. Analyses such as fat, protein, water, or BEFFE are used prior to completion to optimise batch mixing, review product quality, and improve cost-effectiveness.

The ground mass is mixed in an AMP alco mixer by the mixing devices (mixing shafts) in the mixer trough of the machine. The direction of rotation of the shafts can be changed to achieve a perfect, fast thorough mixing. Depending on the application, different mixer sizes (350-1000 l) and mixer shafts, e.g. paddle, spiral or special mixing tool are available. The alco paddle mixer is particularly suitable for product-protecting, yet highly efficient, mixing to a homogeneous mass. Other equipment options include cryogenic liquefied gas or steam to reach the target temperature, as well as various liquid dosing devices. Another optional production step is mixing the products under vacuum to produce a bubble-free product of improved quality and increased protein yield. Heated or coolable mixer troughs with double walls are also available from alco.