Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

EISELE GmbH

ProFood – Hygienic Tube

Zum Produkt

ProFood – Hygienic Tube

Zum Produkt

ProFood – Hygienic Tube

Zum ProduktÜber uns

EISELE – PRECISION AND INNOVATION MADE IN GERMANY

Eisele is a leading manufacturer of high-quality all-metal connectors and an international company within the HENN Connector Group. At our Waiblingen headquarters, we develop, produce, and distribute innovative connection solutions for pneumatics, cooling water, fluids, and compressed air. Over the decades, we have established ourselves as a premium supplier of connection components, setting new standards in quality, durability, and functionality.

Our portfolio includes a wide range of standard fittings as well as numerous customized special solutions. Almost all Eisele products are 100% manufactured in Germany and are available worldwide through our international distribution network and our subsidiary, Eisele Connectors, in Michigan, USA.

EISELE – MORE THAN JUST CONNECTION TECHNOLOGY

With more than 8,000 standard products and 2,000 customized solutions, we offer a unique range of high-performance connection solutions. Our products are characterized by:

✔ Maximum sealing and safety

✔ Extremely robust and durable design

✔ Vacuum suitability for specialized applications

✔ Easy assembly and disassembly

✔ Special fittings for demanding industrial applications

OUR PRODUCT PORTFOLIO

- Cleanline: Hygienic design fittings for the food, pharmaceutical, and packaging industries.

- Basicline: Robust pneumatic fittings for versatile applications.

- Inoxline: Stainless steel push-in fittings for demanding operating conditions.

- Liquidline: High-quality cooling water fittings for closed and open systems.

- Multiline: Modular, configurable couplings for multiple media in one system.

- Hoses & Accessories: Perfectly matched for your applications.

- 2-IN-1 Connector: One fitting – two hose diameters.

- Temperature Sensors: Precision solutions for temperature monitoring.

Whether a series product or a customized special solution – Eisele stands for precision, innovation, and uncompromising quality.

📍 Visit us at IFFA 2025 in Hall 11.0, Booth A24, and discover our latest connection solutions live!

Unsere Produktgruppen

Downloads

Keywords

- Anschlusstechnik / Connector Technology

- Fittings / Mehrfachkupplungen / Multiple couplings

- Edelstahl Komponenten / Stainless steel components

- Hygienic Design / Hygienisches Design

- Lebensmittel Schläuche / Food tubes

Unsere Produkte

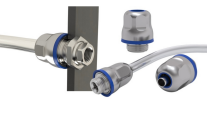

Cleanline - Hygienic Design Connectors

Cleanline – Hygienic Connection Technology for Meat, Sausage, and Alternative Protein Production

In the demanding environment of meat, sausage, and alternative protein production, maintaining the highest hygienic standards is essential. Cleanline technology offers an innovative connection solution specifically designed to meet the requirements of protein-based food processing. It ensures continuous hygiene and minimizes the risk of cross-contamination in critical processing areas, making it an ideal choice for the global food industry.

Optimized Hygienic Design for Critical Applications

Cleanline connections feature a seamless, hygienically optimized design that provides several key benefits:

- Polished Surfaces: Reduce the accumulation of dirt and bacteria.

- Precision-Made Seals: Prevent the ingress of contaminants.

- Robust Materials: Constructed from stainless steel combined with high-quality sealing materials (such as EPDM or FKM, which are FDA compliant).

These characteristics ensure that cleaning is both effective and straightforward—a crucial factor in meat and sausage processing.

Technical Features and EHEDG Certification

Cleanline technology is available in various sizes and configurations to meet the diverse needs of modern production facilities. Key technical specifications include:

- Available Connection Sizes: AD6 (EHEDG-certified), AD8, and AD10.

- Operating Parameters: A temperature range from 0°C to 130°C and a working pressure of up to 10 bar.

- Versatile Applications: Suitable for use in systems with compressed air and cooling water.

The EHEDG certification confirms that these connection solutions comply with internationally recognized hygienic standards, making them ideal for hygiene-critical areas.

Easy Integration and Secure Process Area Separation

A significant advantage of Cleanline technology is its ability to reliably separate hygienic areas from non-sensitive zones within a facility. The specially designed bulkhead connection ensures that:

- Hygienic areas are securely isolated from less critical zones.

- The risk of cross-contamination is minimized.

- Installation and integration into existing systems are both straightforward and time-efficient.

Relevance for Meat and Sausage Production

Maintaining exceptional cleanliness is vital for processing meat and other protein-rich raw materials. Cleanline connections support this by:

- Ensuring a hygienic material flow during slaughter, processing, and further production stages.

- Minimizing the risk of contaminant transfer in critical processing steps.

- Meeting the stringent requirements of sausage and meat product manufacturing.

Sustainability and Future-Proofing

Cleanline technology offers both short-term efficiency and long-term solutions for optimizing production processes:

- Robust Construction: Guarantees reliable performance even under demanding conditions.

- Flexibility: Allows for adjustments to evolving process requirements.

- Sustainability: Supports ongoing improvements in hygienic standards within the food processing industry.

Conclusion

Cleanline technology is a forward-thinking solution for meat and sausage production. Its innovative hygienic design, easy integration into existing systems, and adherence to strict international standards—as confirmed by EHEDG certification—make it a key contributor to product safety and operational efficiency in the protein-based food industry. Cleanline helps achieve the highest hygiene standards and ensures sustainable, future-proof production processes.

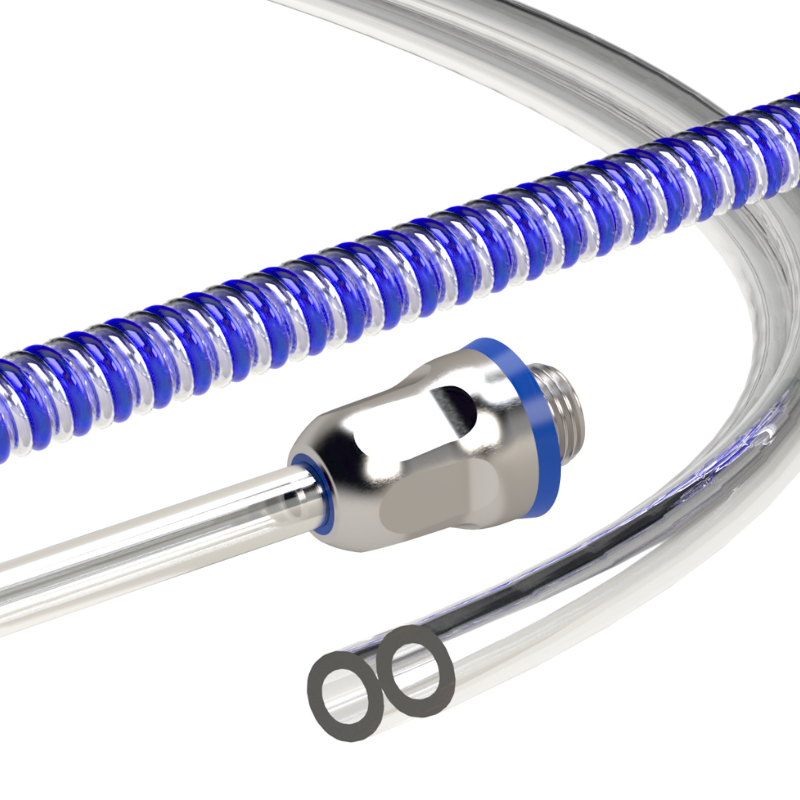

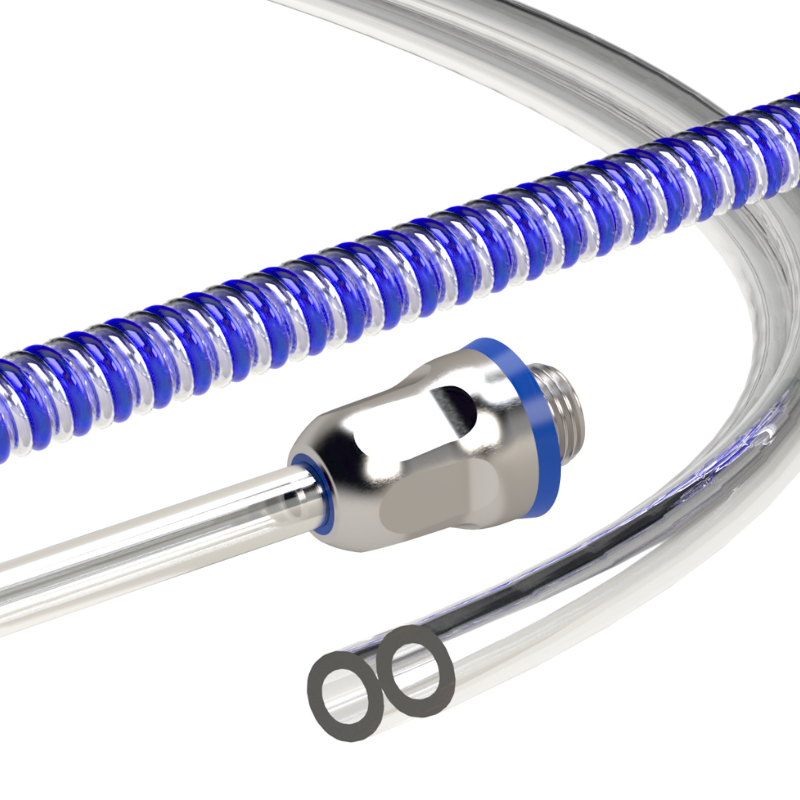

ProFood – Hygienic Tube

ProFood – Hygienic Tubing for Food Processing

In today’s food industry, maintaining the highest level of hygiene is essential. ProFood offers an innovative solution in the form of a high-quality, food-grade tubing system specifically designed for demanding production processes. ProFood combines state-of-the-art material technology with a focus on ease of cleaning and durability – making it ideal for transporting liquids and pasty food products in hygienic systems.

Key Features of ProFood:

- High-Quality Materials: Manufactured from robust polyurethane (PU) and other food-safe materials.

- Optimized Inner Surfaces: Smooth, seamless surfaces that enable effective cleaning.

- Chemical and Temperature Resistance: Engineered to perform under a wide range of conditions in food production.

- Food Safety: Meets stringent hygienic standards and is FDA compliant.

- Compatibility: Ideally pairs with hygienic connection systems to ensure a secure material flow.

- Easy Installation: Flexible and adaptable to various system configurations, enabling quick and simple setup.

Applications and Benefits:

ProFood is excellently suited for use in:

- Filling and packaging lines

- Systems for the transport of liquids and pasty products

- Hygienic production lines in food processing

By implementing ProFood, production processes become not only safer but also more efficient. The tubing plays a significant role in preventing cross-contamination and enhancing product safety – a crucial aspect in the global food industry.

Conclusion:

ProFood is an indispensable component of modern hygienic systems in the food industry. Its innovative material technology, ease of cleaning, and high durability ensure that the highest hygiene standards are consistently met, supporting efficient and safe production processes.

Inoxline - Stainless steel connections

Stainless steel connections: Corrosion-free connection solutions for food processing

In modern production facilities within the food industry—especially in meat, sausage, and alternative protein processing—durability, reliability, and ease of maintenance are essential. Stainless steel connectors provide exactly these benefits: they are rust-free, easily cleanable, and ensure an optimal material flow that meets the high demands of the sector.

Key Features and Benefits

Rust-Free and Robust:

Manufactured from high-quality stainless steel, these connectors offer excellent resistance against corrosion and environmental influences, ensuring long service life and reduced maintenance costs.Easily Cleanable:

Their smooth, polished surfaces allow for quick and effective cleaning, minimizing downtime and enhancing operational safety.Simple Installation and Integration:

Thanks to a modular design, these connectors can be easily integrated into existing systems, ensuring a smooth material flow and optimized production processes.High Temperature and Pressure Resistance:

Designed for challenging operating conditions, stainless steel connectors are ideal for processes that involve varying temperatures and pressures.Versatile Application:

Perfectly suited for use in meat and sausage processing as well as in the handling of alternative protein products—anywhere a reliable, rust-free, and easily cleanable connector is required.

Technical Features

Stainless steel connectors stand out not only for their material quality but also for their technical excellence:

- Precisely manufactured connection elements ensure a secure and leak-free material flow.

- The design allows for fast, tool-free installation, resulting in reduced setup times.

- Their high resistance to temperature and pressure fluctuations ensures smooth operation even in dynamic production environments.

Conclusion

Stainless steel connectors represent a cost-efficient and future-proof solution for modern food processing. Their rust-free, easily cleanable properties and the simple integration into existing systems significantly contribute to meeting the high demands of operational reliability and longevity—a decisive competitive advantage in the global market.

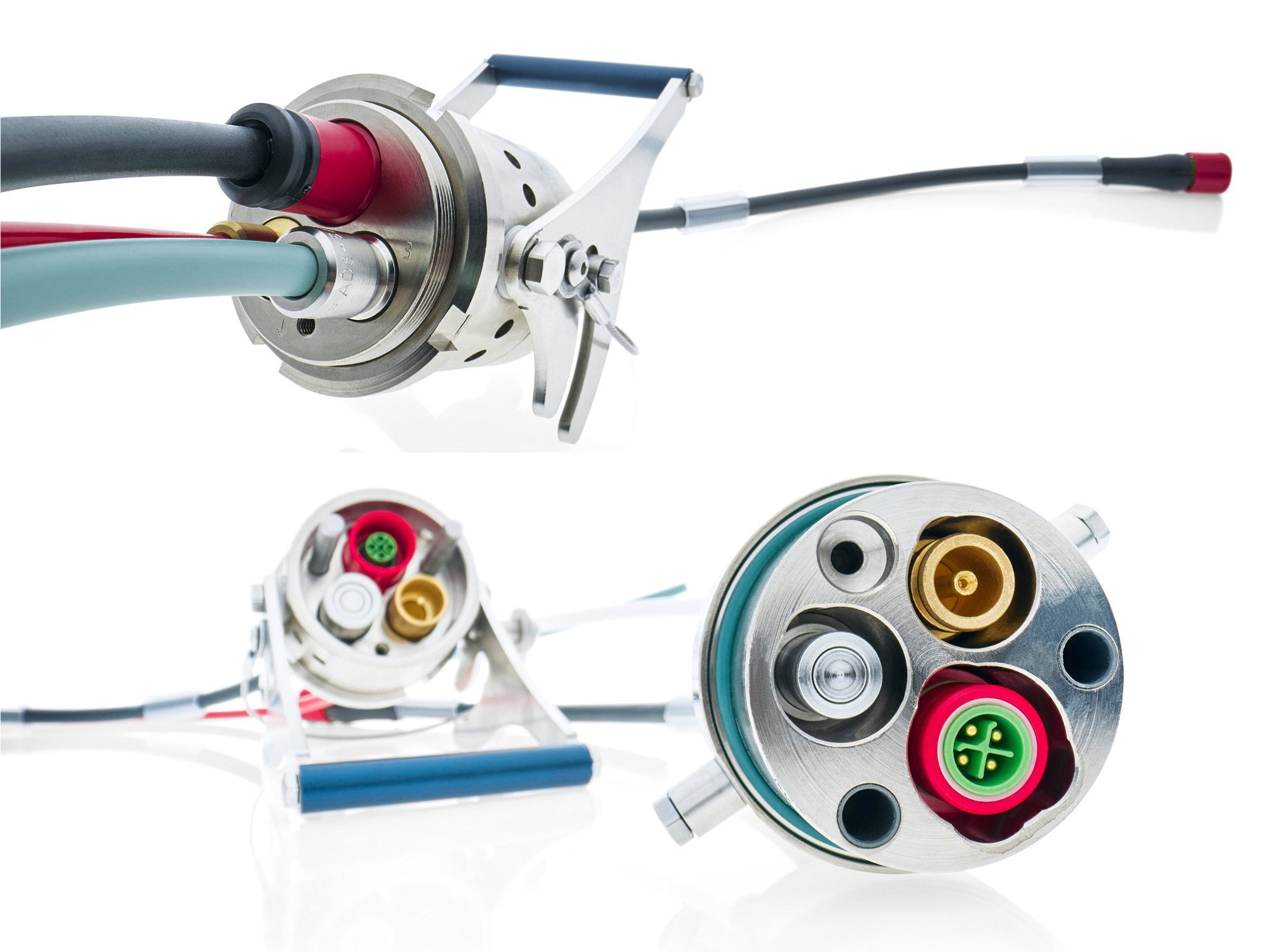

Stainless Steel Multiple Coupling for Flexible Applications in Food Processing

Multiline Adaptiv E: Multiple Coupling for Flexible Applications in Food Processing

In modern production facilities within the food industry—especially in meat, sausage, and alternative protein processing—flexibility is a key success factor. The stainless steel multiple coupling "Multiline Adaptiv E" offers an innovative solution that stands out for its rust-free, easily cleanable construction, ensuring optimal material flow and simple integration into existing systems.

Key Features and Benefits

- High-Quality Stainless Steel Construction:

- Rust-free and durable

- High resistance to corrosion and environmental influences

- Modular, Adaptive Design:

- Flexibly adapts to various process requirements

- Rapid changeover between different connection configurations

- Easy Installation and Integration:

- Tool-free installation enables short setup times

- Optimizes material flow in production

- Technical Excellence:

- High resistance to temperature and pressure

- Precision manufacturing ensures a secure, leak-free material flow

Applications

The "Multiline Adaptiv E" multiple coupling is ideally suited for:

- Meat and sausage processing

- Alternative protein processing

- Other applications requiring a flexible, rust-free, and easily cleanable connection system

Sustainability and Future-Proofing

With its robust stainless steel construction and versatile adaptability, the "Multiline Adaptiv E" represents a sustainable investment. Its low-maintenance properties and ease of cleaning ensure long-term reliable performance in demanding production environments.

Conclusion

The "Multiline Adaptiv E" multiple coupling in stainless steel is a forward-thinking solution for flexible and demanding connection systems in food processing. It combines top-quality materials, simple integration, and versatile adaptability—a clear competitive advantage in a dynamic industry.

Low Dead Space Connections

Low Dead Volume Connectors: Optimal Cleanability and Process Safety in Food Processing

In modern food production, where quality and product safety are paramount, connectors with minimal dead volume are essential. Low dead volume connectors ensure that hardly any residues accumulate in the connection areas – a key advantage for optimizing cleaning processes and minimizing the risk of contamination.

Key Features and Benefits

- Minimal Dead Volume:

- Reduces stagnant fluids and product residues

- Minimizes the risk of cross-contamination

- Optimized Cleanability:

- Smooth, seamless connection surfaces facilitate cleaning

- Enables rapid and effective disinfection cycles

- High-Quality Construction:

- Robust materials and precision manufacturing ensure long-lasting performance

- Ideal for continuous use in demanding production environments

- Easy Integration:

- Compatible with existing hygienic connection systems

- Tool-free installation allows quick adaptation to various system concepts

Applications

Low dead volume connectors are used in various sectors of food processing, especially where consistently high process hygiene is essential:

- Meat and sausage processing

- Processing of alternative protein products

- Other areas where a near dead volume-free material flow is critical for product safety

Conclusion

Low dead volume connectors represent a forward-thinking solution to enhance cleaning efficiency while ensuring the highest process safety in food production. By reducing dead volumes, the risk of contamination is minimized and a smooth, hygienic material flow is maintained – a clear competitive advantage in a dynamic market.