Internationale Suchmaschine für Technologien für Fleisch und alternative Proteine

Stand: Aussteller IFFA 2025

KI-verbessertes DualX+ (IP69K) X-ray Inspektions System

Beschreibung

Künstliche Intelligenz in der Röntgeninspektion verbessert die Genauigkeit

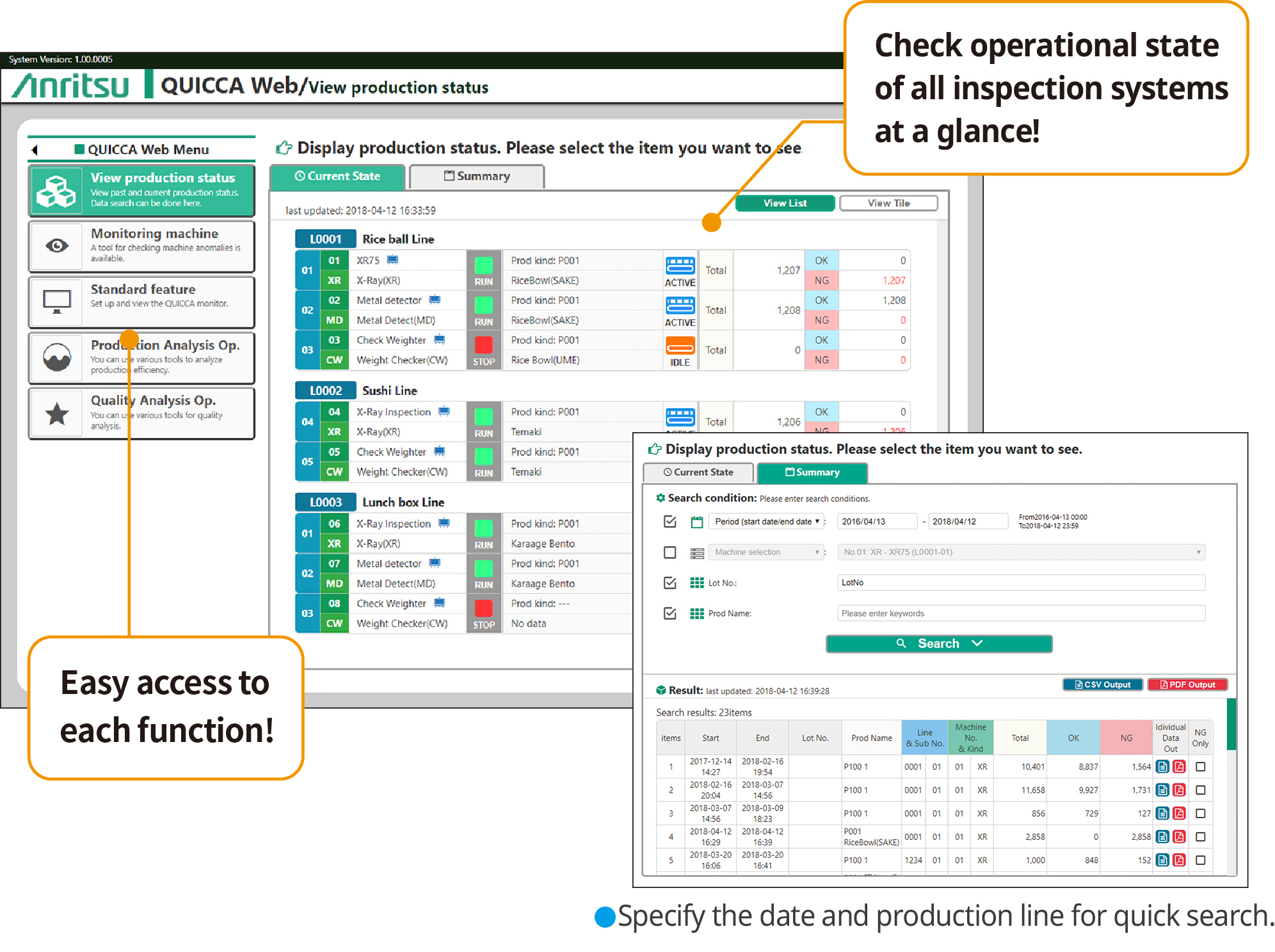

Die Einführung von KI erhöht die Erkennungsgenauigkeit in der Röntgeninspektion. Sie arbeitet neben der traditionellen Bildverarbeitung und verbessert die gesamten Inspektionsfähigkeiten. Aktuelle Systeme haben Schwierigkeiten mit subtilen Defekten und großen Datenmengen aus verschiedenen Produkten. KI bewältigt große Datenmengen hervorragend, lernt und identifiziert automatisch Merkmale. Dies ermöglicht eine hochgenaue Fehlererkennung, reduziert Fehlablehnungen und verbessert die Ausbeute.

Der neue Standard in der Geflügelknochenerkennung

Das Auffinden von Hühnerknochen mit Röntgeninspektion ist schwierig. Das Röntgensystem verbessert die Knochenerkennung erheblich. Es wurde auch vollständig neu konstruiert, um den rauen Bedingungen in Geflügel- und Fleischverarbeitungsbetrieben besser standzuhalten.

Verbesserte Erkennung

Jetzt auf Anritsus bewährter XR75-Plattform bietet dieses zweite Generation Dual-Energie-System eine noch bessere Knochenerkennung und höhere Geschwindigkeit als sein Vorgänger.

IP69K/Hygienisches Design

Das robuste, offene Design fördert eine gründliche Entwässerung und ermöglicht eine zugängliche Hochdruckreinigung. Geneigte Oberflächen, vollständig versiegelte Schweißnähte und ein versiegeltes hygienisches Band minimieren Versteckmöglichkeiten für kontinuierlichen hygienischen Betrieb.

Langlebige Komponenten

Die neu entwickelte Röntgenröhre und der Detektor sollen mindestens zwei Jahre im typischen Betrieb einer Anlage halten.

XR75-Plattform

Produkte sind einfach einzurichten und vom Bediener anpassbar. Die Schnittstelle und Elektronik sind mit anderen XR75-Systemen von Anritsu gemeinsam, was den Benutzern eine einheitliche Erfahrung über die Produktlinien von Anritsu hinweg bietet.

Adresse

Anritsu Corporation

243-8555 Kanagawa Atsugi 5-1-1 Onna Atsugi-shi

Japan

Telefon+81 46-296-6728

Fax+81 46-296-6786

Entdecken Sie mehr von uns